Inquiry

Form loading...

- Phone

- E-mail

In the dynamic landscape of modern packaging and construction industries, the utilization of innovative materials plays a crucial role in enhancing efficiency, sustainability, and product durability. One such material that has garnered significant attention is HDPE (High-Density Polyethylene). Renowned for its robust properties, HDPE material has become a preferred choice for various applications ranging from packaging to structural components in construction. As industry expert Dr. Sarah Thompson, a leading figure in materials science, states, "The versatility and strength of HDPE material make it an indispensable asset in both packaging and construction sectors."

The benefits of HDPE material extend beyond just its impressive physical characteristics. Its resistance to moisture, chemicals, and UV radiation ensures that products remain intact and effective over time, contributing to lower maintenance costs and reduced environmental impact. Furthermore, the lightweight nature of HDPE facilitates easier handling and transportation, making it an economic alternative without compromising quality. In an era where sustainability is paramount, the recyclability of HDPE is another significant advantage, aligning with the growing demand for eco-friendly materials across industries.

As we delve deeper into the top benefits of HDPE material in packaging and construction, it becomes evident that this material not only enhances product performance but also supports a more sustainable future. From reducing the environmental footprint to offering unparalleled durability, the advantages of HDPE are clear, positioning it as a critical material in today's industrial applications.

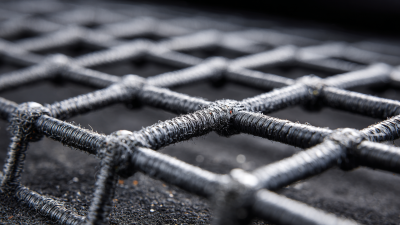

High-Density Polyethylene (HDPE) stands out as a vital material in the packaging and construction industries due to its remarkable durability and resistance to impact. In the packaging sector, HDPE's strength enables it to withstand various environmental stresses, making it an excellent choice for a wide range of applications. The global polyethylene market, valued at $112.45 billion in 2023, is expected to grow to $117.79 billion in 2024 and reach approximately $166.53 billion by 2031, reflecting a compound annual growth rate (CAGR) of 5.07% during the forecast period. This growth is significantly driven by the increasing demand for efficient and sustainable packaging solutions that align with modern consumers' preferences for convenience and portability.

Moreover, the versatility of HDPE meets the changing lifestyles and preferences of consumers, particularly in sectors like food and beverage, electronics, and automotive. The demand for strong, lightweight, and recyclable materials is pivotal as industries respond to consumer trends emphasizing easy handling and transportability. Enhanced attributes, such as high rigidity and resistance to impact, not only contribute to product safety but also extend the lifespan of packaging solutions. As the world shifts towards more sustainable practices, HDPE continues to play an essential role in advancing both economic growth and environmental responsibility in various sectors.

| Benefit | Description | Industry Application |

|---|---|---|

| Durability | HDPE is known for its high strength-to-density ratio, making it highly durable for various applications. | Construction, Packaging |

| Resistance to Impact | It can withstand significant impacts without breaking, making it ideal for protective packaging. | Packaging |

| Chemical Resistance | HDPE is resistant to many chemicals, ensuring safety and integrity of products. | Construction, Agriculture |

| Lightweight | The material is lightweight, reducing handling and transportation costs. | Packaging, Shipping |

| Environmental Sustainability | HDPE is recyclable and can be reused, promoting environmental sustainability. | Packaging, Consumer Goods |

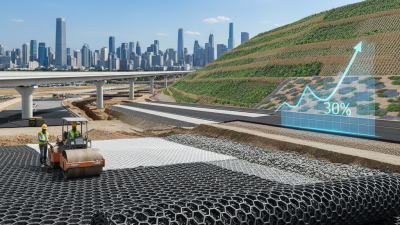

High-Density Polyethylene (HDPE) has emerged as a transformative material in both packaging and construction industries, primarily due to its environmental advantages. According to a report by the American Chemistry Council, HDPE is one of the most recycled plastics in the world, with a recycling rate of about 30% in the U.S. This high recyclability stems from its chemical structure, which allows it to be reprocessed and reused in various applications, reducing the need for virgin materials. Additionally, the Global Plastics Alliance reports that recycled HDPE reduces greenhouse gas emissions by approximately 1.5 tons CO2 equivalent per ton of plastic recycled, highlighting the significant environmental benefits of adopting HDPE.

Sustainability is further bolstered by HDPE's ability to withstand harsh environmental conditions, which means products made from this material tend to have a longer lifespan and require less frequent replacement. The European Commission has identified that the use of HDPE in construction can lead to energy savings of up to 60% compared to traditional materials due to its durability and insulation properties. Furthermore, HDPE’s low-energy requirements during production—about 30% less than that of glass or metal—add to its sustainability profile. These factors collectively position HDPE as a leading choice for environmentally conscious companies aiming to minimize their ecological footprint while achieving functional and durable performance.

High-Density Polyethylene (HDPE) is becoming increasingly popular in the construction industry not only for its durability but also for its cost-effectiveness. One of the primary economic advantages of using HDPE is its long lifespan, which reduces the frequency and costs associated with replacements and repairs. Moreover, the lightweight nature of HDPE means lower transportation costs, which can be significant in large construction projects. By integrating HDPE into their designs, builders can achieve substantial savings over time.

Tips: When considering HDPE for your construction projects, evaluate the overall lifecycle costs rather than just the initial purchase price. Additionally, seek suppliers who offer HDPE products with recycled content to enhance sustainability and reduce environmental impact, which can also yield potential cost benefits.

The economic impact of HDPE extends beyond just savings on materials. Its adaptability allows for innovative design solutions, increasing the efficiency of construction processes. Projects using HDPE often face fewer delays due to its resistance to environmental stressors like moisture and chemicals, further streamlining operations and enhancing profitability.

Tips: Always collaborate with engineers who are knowledgeable in HDPE applications, as they can provide insights on optimizing its use in your projects, ultimately leading to better budget management and project outcomes.

High-density polyethylene (HDPE) is gaining recognition for its versatility across both packaging and construction industries. In the packaging sector, HDPE is extensively utilized due to its robustness and resistance to various chemicals, making it ideal for products such as plastic bottles and containers. Additionally, its lightweight nature and recyclability further enhance its appeal, providing sustainable solutions to manufacturers and consumers alike. The ability to produce HDPE in various forms, including sheets and films, allows for diverse applications that cater to the specific needs of the food, beverage, and personal care industries.

In the construction industry, HDPE’s strength and durability make it a preferred material for a range of applications including piping, geomembranes, and construction materials. It is resistant to corrosion and UV degradation, which contributes to its long lifespan in outdoor environments. The flexibility of HDPE also supports innovative building designs, enabling seamless integration into various structural applications. As a result, both sectors benefit from the widespread use of HDPE, showcasing its essential role in advancing sustainable practices within packaging and construction.

HDPE, or High-Density Polyethylene, is increasingly recognized for its non-toxic properties, making it a preferred choice in both packaging and construction industries. One of the primary advantages of using HDPE is its compliance with health and safety regulations. Unlike some plastics that may leach harmful chemicals, HDPE is free from BPA and phthalates, ensuring that products packaged in this material remain safe for consumers and the environment. This characteristic not only enhances the safety of food packaging but also addresses growing concerns over toxic exposure in various applications.

In addition to its non-toxic nature, HDPE meets stringent regulatory standards set by health organizations worldwide. This compliance boosts consumer confidence in products made from HDPE, as manufacturers can assure customers that their goods adhere to safety guidelines. Whether it's in the form of bottles, containers, or construction materials, HDPE’s robust health and safety credentials make it an ideal option for industries looking to promote sustainability and safety. As regulations evolve to prioritize safer materials, the demand for HDPE will likely continue to rise, benefiting both manufacturers and consumers alike.