Inquiry

Form loading...

- Phone

- E-mail

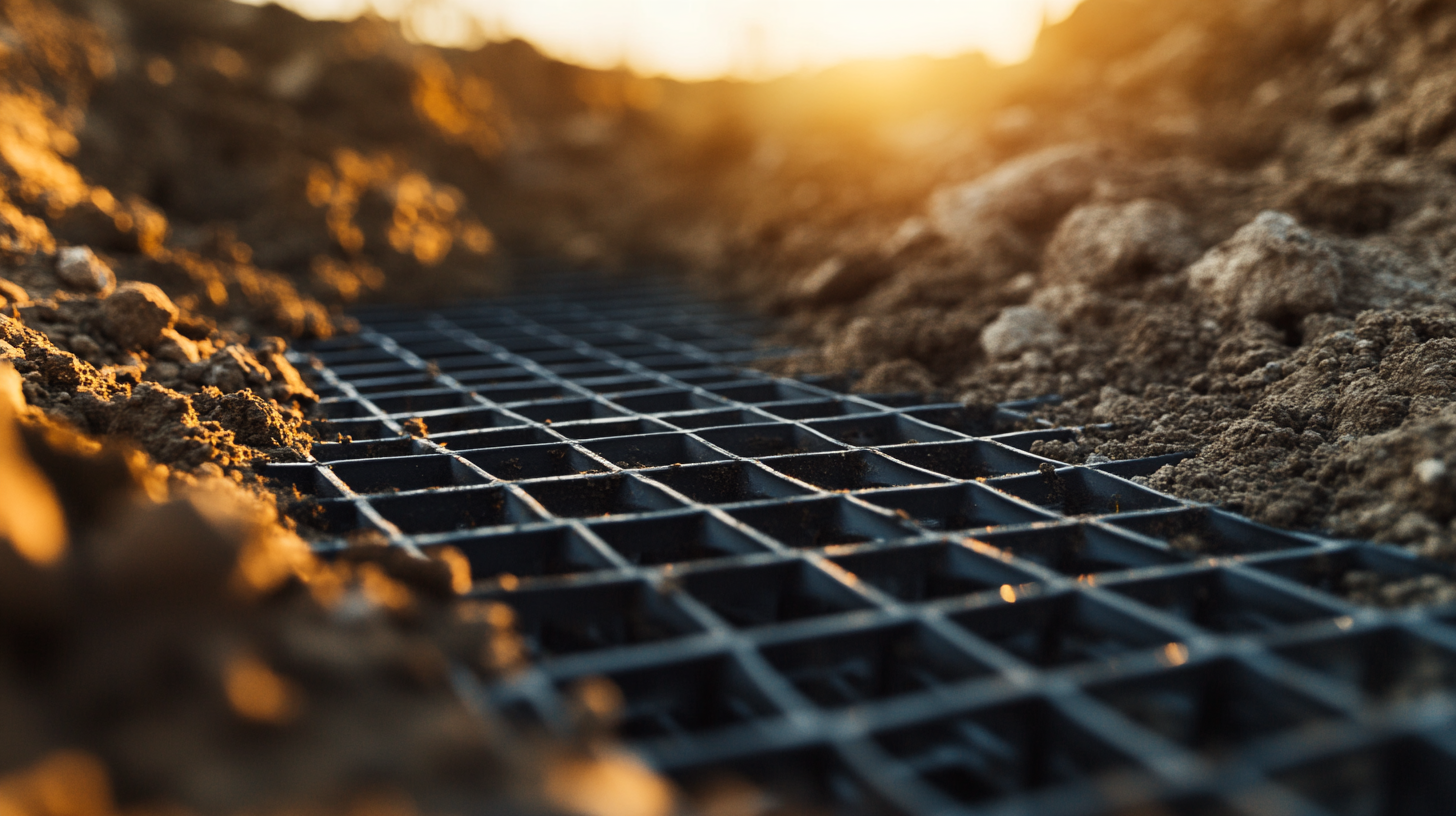

When embarking on a construction or landscaping project, the importance of selecting the right materials cannot be overstated, particularly when it comes to soil stabilization and reinforcement. One critical component that often goes overlooked is the Soil Reinforcement Geogrid. This versatile material plays a pivotal role in enhancing soil strength, improving load distribution, and preventing erosion, making it an ideal choice for various applications, from road construction to retaining walls.

However, with the myriad of options available in the market, choosing the best Soil Reinforcement Geogrid for your specific needs can be daunting. This blog will provide an essential checklist outlining the benefits of different types of geogrids and key factors to consider, ensuring your project achieves lasting stability and durability. By understanding the advantages and characteristics of soil reinforcement geogrids, you can make an informed decision that will enhance the overall success of your undertaking.

When selecting soil reinforcement geogrids for your project, it's essential to consider several key factors that can significantly impact the effectiveness of your soil stabilization efforts. First, the material composition of the geogrid plays a crucial role in its performance. Most geogrids are made of polymers, which offer durability and resistance to environmental factors. Ensure that the selected geogrid is suited for the specific soil conditions and loading requirements of your project.

Another important factor is the design and structural configuration of the geogrid. The geometry of the apertures and the overall grid pattern can influence how well the geogrid interlocks with the soil particles, which is vital for achieving the desired reinforcement effect. Additionally, consider the tensile strength and elongation properties, as these will determine how the geogrid handles loads and stresses in various conditions. Proper assessment of these elements will help ensure that the chosen geogrid effectively contributes to soil stabilization and erosion control.

| Factor | Description | Importance |

|---|---|---|

| Material Composition | Check if the geogrid is made of high-quality polymers for durability. | High |

| Tensile Strength | Ensure the geogrid has adequate tensile strength to withstand forces. | Critical |

| Aperture Size | Evaluate the aperture size for soil interlock and drainage. | Moderate |

| UV Resistance | Verify resistance to ultraviolet radiation for outdoor applications. | High |

| Installation Ease | Consider how easy it is to install the geogrid on site. | Moderate |

| Cost | Analyze the cost relative to performance for budget considerations. | High |

| Project Compatibility | Ensure the geogrid is suitable for the specific project requirements. | Essential |

When selecting a soil reinforcement geogrid for your project, it's crucial to understand the different types available and their specific applications. Geogrids are designed to enhance the mechanical properties of soil, providing stability and support in various construction scenarios. There are primarily two categories of geogrids: uniaxial and biaxial. Uniaxial geogrids are engineered for soil reinforcement in one direction, making them ideal for retaining walls and steep slopes. Their ability to withstand high tensile forces in a single direction ensures that they excel in applications where vertical load transfer is essential.

On the other hand, biaxial geogrids offer reinforcement in multiple directions, which is advantageous for applications such as base stabilization under roads and pavements. By distributing loads evenly across the grid's structure, they help prevent soil deformation and prolong the lifespan of paved surfaces. Additionally, composite geogrids, which combine the properties of both types, are often used in more complex engineering projects, offering enhanced strength and flexibility. Understanding the specific requirements of your project will guide you in choosing the appropriate geogrid type to ensure optimal performance and durability.

When selecting a geogrid manufacturer for soil reinforcement projects, it's crucial to assess several key criteria that can determine the overall quality and effectiveness of the product. First, evaluate the manufacturer's experience and reputation within the industry. A report by Geosynthetic Research Institute (GRI) states that over 80% of successful projects involved manufacturers with a proven track record of at least 10 years. This longevity often translates to reliable products backed by extensive testing and quality assurance protocols.

Secondly, consider the technical specifications and test certifications that the manufacturer provides. According to a study conducted by the International Geosynthetics Society (IGS), geogrids that undergo rigorous testing such as ASTM D6637 for tensile strength significantly outperform those that do not. Look for manufacturers who follow these industry standards and offer clear documentation of their testing results. This transparency not only indicates confidence in their products but also establishes trust in their ability to meet project requirements effectively.

Lastly, assess the range of products and customization options available. Flexibility in design and material choice can greatly enhance project outcomes. The Global Geosynthetics Market Report indicates that companies providing tailored solutions reported a 25% increase in client satisfaction. By focusing on these criteria, project managers can make informed decisions that positively influence the success of their soil reinforcement initiatives.

When it comes to selecting the best soil reinforcement geogrid for your project, understanding comparison metrics such as cost, durability, and performance is crucial. Cost plays a significant role in decision-making; however, it's essential to evaluate the long-term benefits of investing in a higher-quality geogrid. While some options may appear economical upfront, their performance could decline faster over time, leading to increased maintenance costs.

Durability is another key factor to consider. A geogrid's ability to withstand environmental stressors and project-specific loads will greatly affect its lifespan. Look for products that offer robust UV resistance and compatibility with various soil types. Incorporating tips such as seeking out third-party certifications can provide assurance of the geogrid's quality, helping you make a more informed choice for your project.

Lastly, performance metrics are vital to ensure that the geogrid effectively meets project requirements. Focus on how well the material can distribute loads and maintain ground stability. Asking for case studies or performance data from manufacturers can aid in comparing different options. Ultimately, a thorough evaluation of these metrics will empower you to select the ideal geogrid that aligns with both your budget and project goals.

When selecting the best soil reinforcement geogrid for your project, collaborating with a reputable supplier can significantly enhance the effectiveness and longevity of your structures. According to a recent report by Geosynthetic International, properly designed geogrids can reduce soil settlement by up to 80%, making them an essential component for infrastructure projects. Working with established suppliers ensures that you receive high-quality materials that meet industry standards, which is critical for the success of your project.

Moreover, reputable suppliers often provide access to advanced design software and expert advice, helping you choose the most suitable geogrid for your specific application. A study by the International Geosynthetics Society indicates that projects utilizing engineering support from reputable suppliers saw a 15% reduction in construction time and costs. Access to such resources can be invaluable, particularly for complex projects where soil conditions and loading environments can vary widely. By partnering with a trusted supplier, you not only optimize material selection but also improve overall project efficiency.