Inquiry

Form loading...

- Phone

- E-mail

Choosing the right HDPE geomembrane for your project is crucial. According to Dr. John Smith, a renowned expert in geomembrane technology, “The effectiveness of a geomembrane often depends on the right selection process.” This highlights the importance of understanding the factors that influence choice.

When selecting an HDPE geomembrane, consider the project’s specific needs. Various factors come into play, such as the thickness, texture, and environmental conditions. Each decision impacts durability and performance. The landscape can be unforgiving, and a poor choice may lead to costly repairs.

Moreover, not all projects are the same. What works for one may not work for another. Evaluating the project site and its challenges is essential. Feedback from past projects can guide current decisions, but many overlook this step. It’s vital to learn from mistakes to avoid repeating them. The right HDPE geomembrane can ensure project success and sustainability.

When selecting HDPE geomembranes for projects, several critical factors must be considered. The thickness of the geomembrane is paramount. Standard thicknesses range from 20 to 120 mils. A thicker membrane provides better puncture resistance but may cost more. Too thin a geomembrane can lead to failures, especially under pressure or when exposed to harsh elements.

The chemical compatibility of HDPE with the environment is also crucial. Reports indicate that HDPE is resistant to many chemicals, including acids and bases. However, specific applications may require testing to ensure compatibility. This step is often overlooked, leading to potential functional failures in the long run.

Tips: Always request test data from suppliers. Look for documents showing the product's performance under various conditions. Understanding environmental impacts, like temperature fluctuations, can guide material selection.

Consider the installation process. HDPE geomembranes require skilled labor to ensure proper installation. Misalignment or poor sealing can jeopardize their effectiveness. Regular training for installation crews can mitigate these risks. However, even with training, human error is always a concern. Improper installation remains a common issue across projects. Always plan for potential setbacks during the installation phase.

When selecting the best HDPE geomembrane for a project, understanding the available types is crucial. HDPE geomembranes vary in thickness, texture, and application. Standard thicknesses range from 30 mil to 80 mil. Thicker membranes offer better puncture resistance, which is vital for projects in harsher environments.

Some geomembranes have a smooth surface, while others are textured. Textured options improve friction, which can be beneficial in slopes or containment applications. The choice of texture impacts installation and long-term performance. However, selecting a textured option may require more careful handling during installation.

Customization is another aspect that may lead to confusion. Different projects have unique needs. Not all environments require the thickest or most durable option. Evaluating specific project conditions is essential. The wrong choice can lead to leaks or failures. It's vital to reflect on these factors during the decision-making process. Each choice carries implications for longevity and performance. Balancing cost with functionality is an ongoing challenge for many.

This chart illustrates the various types of HDPE geomembranes available and their typical thicknesses used in different applications.

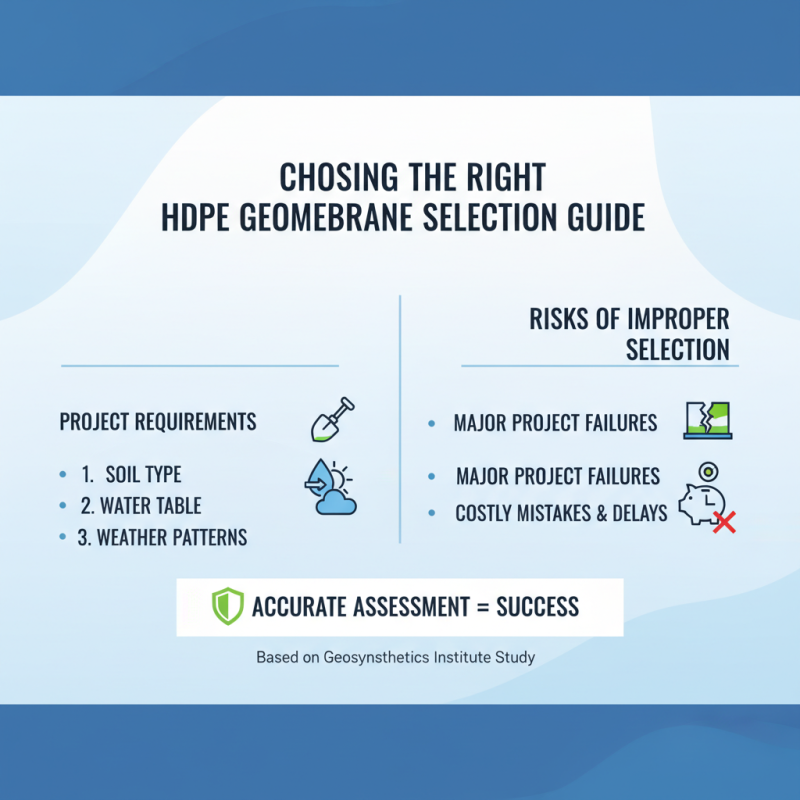

Choosing the right HDPE geomembrane for your project begins with a thorough evaluation of project requirements and environmental conditions. Consider factors such as soil type, water table levels, and local weather patterns. According to a comprehensive study by the Geosynthetics Institute, improper installation or selection can lead to major project failures. Accurate assessments can prevent costly mistakes and delays.

Existing data suggests that temperature fluctuations and UV exposure substantially impact geomembrane longevity. The lifespan of HDPE geomembranes typically ranges from 20 to 30 years, contingent upon the conditions they endure. Projects in extreme climates may need enhanced materials.

**Tip:** Always conduct site-specific testing before finalizing your geomembrane choice. Analyzing the site's chemical compatibility with HDPE is vital. This ensures that the material won't degrade prematurely.

For optimal performance, remember that even minor details matter. Evaluate potential puncture risks, especially in high-traffic areas. Recognizing these nuances can guide your material selection process. The right choice can prevent leaks and environmental contamination. Keep your project’s durability and sustainability at the forefront.

When selecting the best HDPE geomembrane, understanding quality standards and manufacturer certifications is crucial. According to the Geosynthetic Research Institute, reliable geomembranes should meet ASTM and GRI standards. These standards ensure that the material is durable and effective for various applications, such as landfill liners and water containment.

Tips: Check for certifications like ISO 9001. This designation confirms that manufacturers follow strict quality control measures. Also, look into material properties, such as tensile strength and UV resistance. A solid geomembrane will resist punctures and tears.

Many manufacturers have varying degrees of compliance. Some may meet basic requirements while others go beyond. It’s essential to assess the long-term performance and environmental impact. Reports indicate that geomembranes can last over 30 years if made under strict quality guidelines. However, not all companies adhere to these criteria. Make sure to audit their compliance authentically. Verify their history and client reviews.

Tips: Always ask for test data and material samples. Inspect the documentation carefully. It pays to be thorough. Some manufacturers may have gaps in testing. Don't be afraid to dig deeper.

When budgeting for HDPE geomembrane installation, understanding costs is vital. Various factors influence the price. The thickness of the geomembrane can vary, affecting the overall budget. Thicker materials offer more durability but are often more expensive. Additionally, geographical location can play a significant role. Transportation fees might skyrocket if your project is far from suppliers.

Labor costs should not be overlooked. Hiring skilled workers is crucial for a successful installation. However, skilled labor typically comes at a higher price. Misestimating these costs can lead to financial strain. It can also result in project delays, further impacting your budget.

Remember to factor in unexpected expenses. Things rarely go completely as planned. Site preparation might require more resources than anticipated. Also, post-installation maintenance is often neglected in initial budgeting. Proper planning for contingencies can prevent future stress. It’s a complex process, and reflecting on each element can lead to better financial outcomes.