Inquiry

Form loading...

- Phone

- E-mail

When considering optimal drainage solutions, Geotextile Drainage Fabric stands out as a superior choice. Dr. Emily Carter, a leading expert in geotechnical engineering, emphasizes, "Geotextile Drainage Fabric enhances site stability while efficiently managing water flow." This statement reflects the multiple benefits that such fabrics bring to any construction project.

Using Geotextile Drainage Fabric can minimize soil erosion, reduce water pooling, and ensure longevity in structures. The material is designed to be permeable, allowing water to pass through while filtering out particulate matter. This process protects the integrity of surrounding soils and substrates. However, improper installation can compromise its effectiveness.

Project managers often overlook the importance of selecting the right fabric type. Not all geotextiles are the same; specific applications require tailored selections. It’s essential to assess soil conditions and drainage needs carefully. Making informed decisions about the use of Geotextile Drainage Fabric can mean the difference between success and rework on a project.

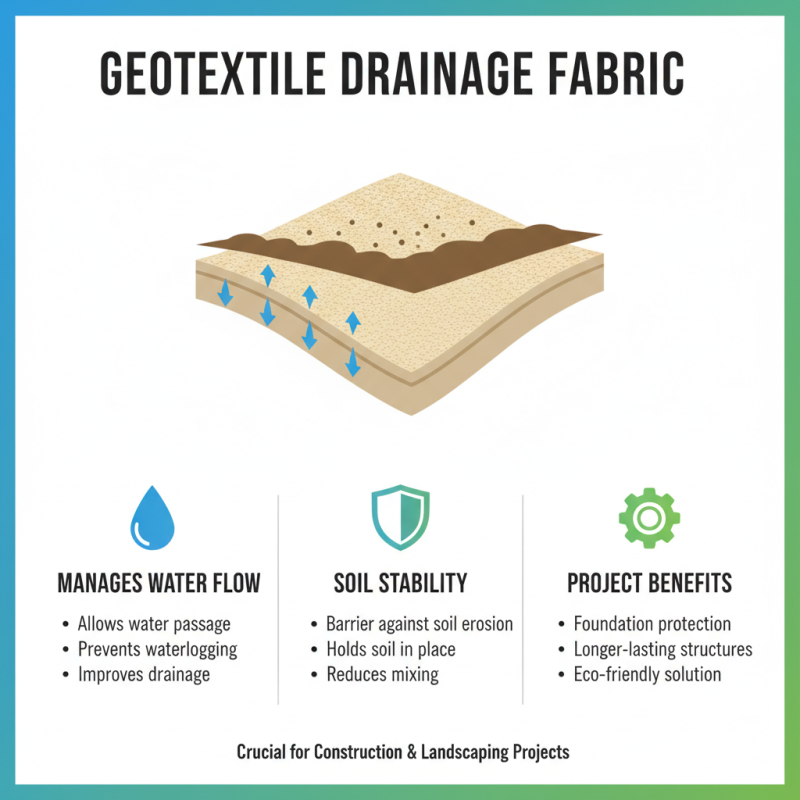

Geotextile drainage fabric is a crucial component in various construction and landscaping projects. This fabric serves multiple purposes, primarily focused on managing water flow and soil stability. It creates a barrier that allows water to pass while preventing soil erosion. By using geotextile fabric, projects benefit from reduced waterlogging and improved drainage efficiency.

One application of geotextile drainage fabric is in retaining walls. The fabric helps to manage hydrostatic pressure behind the wall. This control is essential in preventing structural failure. It can also be used in road construction, where proper drainage is crucial for longevity. Improper use or installation might lead to water pooling and reduced effectiveness.

Tips: Always check for punctures before installation. They can weaken the fabric. Additionally, consider the local soil type. Poor compatibility can result in unexpected issues. Regular inspections after installation can prevent costly repairs. Proper maintenance is key to maximizing the effectiveness of your geotextile drainage fabric.

Geotextile drainage fabric serves as a vital component in construction projects. It helps control soil erosion and enhances drainage. This material is lightweight yet robust, making it easy to install. It can separate soil layers, preventing sediment from clogging drainage systems. Such separation is crucial in maintaining effective water flow.

Using geotextile fabric also aids in stabilizing soil. It provides support for roads and structures, reducing the risk of settling or shifting. Projects benefit from improved longevity when the right materials are utilized. However, the installation process can be tricky. If not laid correctly, issues may arise later. Over time, some fabric may degrade or become ineffective. Regular inspections and maintenance are essential for ensuring optimal performance.

The versatility of geotextile drainage fabric is noteworthy. It can adapt to various terrains and project types. From highways to landscaping, it finds use in diverse applications. Yet, it's important to evaluate the specific needs of each project. Not all areas require the same type or thickness of fabric. Assessing soil characteristics is crucial. The wrong choice can lead to unforeseen challenges.

When selecting geotextile drainage fabric, several key factors deserve attention. First, consider the fabric's permeability. The right permeability ensures that water flows freely while retaining soil particles. A highly permeable fabric can enhance drainage efficiency. However, too much permeability may lead to soil loss. It's essential to strike a balance.

Next, look at the tensile strength of the fabric. Strong materials resist tearing and deformation under load. This strength is vital in high-traffic areas or projects with significant weight. But remember, stronger doesn't always mean better. Some projects benefit from softer, more flexible fabrics that adapt to soil movement.

Finally, the type of soil and its properties impact your choice. Different soils have varying drainage needs. Coarse soils may require different fabrics compared to fine, clay-like soils. It's often a trial and error process to find the best fit. Indeed, understanding local conditions can be a challenge, but it's a crucial step toward successful drainage solutions.

Geotextile drainage fabric plays a crucial role in effective water management projects. Proper installation techniques ensure its effectiveness and longevity. Start by preparing the site thoroughly. Clear debris and ensure the area is level. This step is vital. Uneven surfaces can lead to water pooling and reduced drainage efficiency.

When laying the fabric, overlap the seams by at least 12 inches. This prevents soil from contaminating the drainage layer. According to industry reports, a proper overlap can enhance drainage by up to 20%. Ensure the fabric is taut but not overly stretched. Loose fabric can cause wrinkles that trap water.

**Tip:** Always test the drainage capability after installation. Use water to simulate heavy rainfall. Check for pooling or slow drainage areas. If issues arise, adjustments may be necessary.

Monitoring the fabric after installation is essential. Regular inspections can help identify wear and tear. Make sure to replace sections if necessary. Geotextile can last for years if maintained well. Remember, good drainage practices lead to project success.

Geotextile drainage fabric plays a critical role in modern construction and environmental projects. These materials are designed to manage water effectively, reducing erosion and improving soil stability. With increasing emphasis on sustainability, choosing geotextile solutions can have a positive environmental impact.

These fabrics assist in filtering pollutants from runoff. They also help in maintaining groundwater levels, which is crucial for local ecosystems. Proper use can lead to a reduction in waterlogging, benefitting nearby flora and fauna. However, there are concerns about the materials themselves. Some fabrics may not be biodegradable, leading to long-term waste issues. It raises questions about their life cycle and end-of-life disposal.

When considering sustainability, it's essential to weigh the benefits against potential downsides. Local conditions can greatly affect the performance of these fabrics. Sometimes, they may not perform as expected, leaving unforeseen consequences. Ongoing studies are necessary to fully understand their long-term environmental implications. Assessing these factors is vital in making informed decisions that prioritize both project success and ecological integrity.

| Aspect | Details |

|---|---|

| Material Type | Polypropylene, Polyester |

| Durability | 15-30 years depending on environmental conditions |

| Sustainability | Recyclable, reduces soil erosion |

| Environmental Impact | Minimizes disturbance to habitats |

| Water Management | Effective drainage, enhances groundwater recharge |

| Cost Efficiency | Reduces maintenance costs |