Inquiry

Form loading...

- Phone

- E-mail

In an era where environmental protection is more crucial than ever, the materials we choose for our projects can significantly impact sustainability efforts. One innovative solution that stands out in the field of environmental protection is the use of HDPE geomembrana, a high-density polyethylene liner extensively used in various applications, including waste containment, water management, and soil stabilization. This versatile material has garnered attention for its remarkable durability and environmental resistance, making it a preferred option for engineers and environmentalists alike.

HDPE geomembrana offers numerous advantages, including excellent chemical resistance, UV protection, and a long lifespan, making it an ideal choice for projects requiring robust and reliable barriers against pollutants. Its lightweight nature facilitates easy installation, while its flexibility allows it to adapt to various project demands. As we explore the reasons to choose HDPE geomembrana for your environmental protection needs, we will delve into its benefits, applications, and the positive impact it can have on promoting sustainability and safeguarding natural resources for future generations. By selecting HDPE geomembrana, you are not just making a choice for a superior material, but also committing to a more sustainable approach in environmental management.

HDPE geomembranes are increasingly recognized for their pivotal role in environmental protection across various applications. One of the primary benefits of using HDPE geomembranes is their exceptional durability and resistance to chemical degradation. This makes them ideal for containing hazardous materials, preventing leaks from landfills and containment ponds that could potentially harm groundwater or soil quality. Their robustness ensures long-term performance, even in harsh environmental conditions, thereby safeguarding ecosystems from contamination.

Moreover, HDPE geomembranes are highly versatile and can be tailored to meet specific requirements of different projects. They are lightweight and easy to install, which not only reduces labor costs but also simplifies the process of land rehabilitation and environmental restoration. Additionally, their impermeable nature aids in effective stormwater management, allowing facilities to control and treat runoff effectively. By integrating HDPE geomembranes into environmental projects, organizations can enhance sustainability efforts while ensuring compliance with environmental regulations.

HDPE geomembranes are renowned for their exceptional durability, making them an ideal choice for various environmental protection applications. One of their key properties is their ability to withstand harsh conditions, including extreme temperatures and UV exposure. This resilience ensures that they maintain their structural integrity over time, effectively preventing leaks and contamination in projects such as landfill liners, wastewater treatment facilities, and mining operations. The longevity of HDPE geomembranes reduces the need for frequent replacements, ultimately contributing to more sustainable environmental management practices.

In addition to their durability, HDPE geomembranes exhibit outstanding chemical resistance. They can tolerate a wide range of chemicals, including acids, alkalis, and solvents, which often pose challenges in environmental applications. This characteristic is particularly crucial in protecting soil and water resources from potential pollutants. By providing a reliable barrier against chemical leaching, HDPE geomembranes ensure that projects are compliant with environmental regulations and safeguard public health. Overall, the combination of durability and chemical resistance makes HDPE geomembranes a valuable asset for various environmental protection needs.

HDPE geomembranes offer remarkable durability and chemical resistance that make them ideal for various environmental protection applications. This bar chart illustrates the performance ratings of key properties that HDPE geopmembranes possess, demonstrating their overall effectiveness.

When it comes to waste management solutions, High-Density Polyethylene (HDPE) geomembranes stand out due to their cost-effectiveness and durability. According to the U.S. Environmental Protection Agency (EPA), the implementation of HDPE geomembranes in landfills can significantly reduce leachate migration, which not only protects the environment but also minimizes the costs associated with groundwater remediation. The longevity and resilience of HDPE allow for reduced maintenance costs over time, making it an ideal choice for both short-term and long-term waste management projects.

In a comprehensive study conducted by the Geosynthetic Research Institute, it was reported that the installation of HDPE geomembranes can lead to a 20% decrease in overall project costs when compared to other materials. This is largely attributed to HDPE's lightweight properties, which ease transportation and installation expenses. Furthermore, the material’s resistance to chemical degradation ensures fewer replacement and repair needs, translating to long-term savings. With waste generation expected to increase by 70% by 2050, investing in efficient and sustainable solutions like HDPE geomembranes is not only economically wise but also essential for environmental preservation.

When it comes to landfill applications, choosing the right geomembrane is crucial for effective environmental protection. High-Density Polyethylene (HDPE) geomembranes stand out in this comparative analysis against other geomembrane materials like PVC and LDPE. One of the primary advantages of HDPE is its superior resistance to chemical and environmental stresses, making it ideal for lining landfills. While PVC offers flexibility, it tends to be less durable under harsh conditions, which can lead to leakage and contamination over time. LDPE, while also flexible, lacks the tensile strength that HDPE provides, rendering it less effective in applications where heavy loads and sharp objects are present.

Tips for selecting the right geomembrane for your project include considering the specific environmental conditions of the landfill site. HDPE's robustness makes it suitable for areas with varying soil compositions and potential exposure to hazardous materials, ensuring a long-lasting solution that minimizes environmental risks. Additionally, it’s essential to evaluate the installation process, as some materials require more careful handling than others. Always consult with industry experts to assess the best material based on your site-specific needs and regulatory requirements. This approach not only guarantees compliance but also enhances the overall sustainability of your environmental protection efforts.

| Material Type | Tensile Strength (MPa) | UV Resistance | Thickness Range (mm) | Cost ($/m²) | Environmental Impact |

|---|---|---|---|---|---|

| HDPE | 25 | Excellent | 0.5 - 3.0 | 1.00 - 2.50 | Low |

| LDPE | 20 | Good | 0.5 - 2.5 | 0.80 - 2.00 | Medium |

| PVC | 15 | Fair | 1.0 - 3.5 | 1.50 - 3.00 | High |

| CPE | 18 | Good | 1.0 - 3.0 | 1.20 - 2.80 | Medium |

| EPDM | 22 | Excellent | 1.0 - 2.5 | 1.70 - 3.50 | Low |

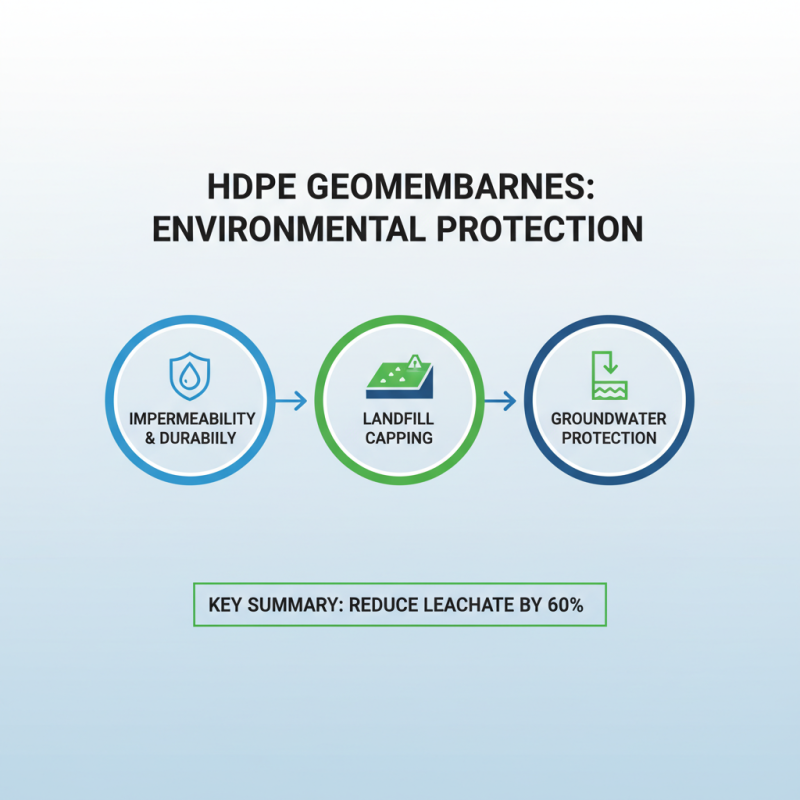

HDPE geomembranes have become a vital component in various environmental protection projects due to their excellent impermeability and durability. Case studies illustrate their successful applications across different sectors. For instance, in landfill capping projects, HDPE geomembranes effectively prevent leachate migration, thereby safeguarding groundwater resources. A study conducted by the Geosynthetic Research Institute highlighted that utilizing HDPE geomembranes in landfill operations can reduce leachate production by up to 60%, significantly diminishing environmental risks.

Another prominent application of HDPE geomembranes is in the construction of containment facilities for hazardous waste. A case study in California demonstrated a project that utilized HDPE geomembranes to create a barrier that safely contained toxic substances. The project reported a 98% effectiveness rate in preventing groundwater contamination, showcasing the material's robustness. According to a report by the International Geosynthetics Society, the long-term performance of HDPE geomembranes in such applications is attributed to their resistance to chemicals and UV radiation, making them an ideal choice for environments that demand high resilience.

Similarly, in the water conservation sector, HDPE geomembranes have proven effective in reducing evaporation from reservoirs. An initiative in arid regions revealed that the implementation of HDPE liner systems resulted in a reduction of water loss by up to 80%, thus promoting more sustainable water management practices. These case studies collectively emphasize the critical role of HDPE geomembranes in advancing environmental protection efforts, demonstrating their versatility and effectiveness in various applications.