Inquiry

Form loading...

- Phone

- E-mail

Choosing the right Pp Geotextile for your project can be challenging. It affects the efficiency of your work and its outcome. John Smith, a leading expert in geosynthetics, emphasizes, "Selecting the appropriate geotextile can significantly enhance project performance." This highlights the importance of making an informed decision.

Pp Geotextile offers various benefits, including soil stabilization and drainage. However, with many options available, it may be overwhelming. Key factors include material durability, permeability, and application type. Underestimating these details can lead to project failures.

Moreover, not all Pp Geotextile products are created equal. Each project has unique requirements. Understanding your specific needs is essential. A thoughtless choice might result in additional costs or delays. Thus, a careful evaluation process is vital for achieving success in your project.

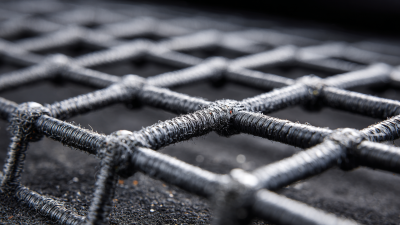

PP geotextiles are essential materials in various construction and landscaping projects. They are made from polypropylene and designed to provide durability and strength. These textiles prevent soil erosion, improve drainage, and separate different materials. Their applications range from road construction to landfills and even gardening. Understanding their properties is key to maximizing their benefits.

When selecting PP geotextiles, consider the project requirements. The weight, thickness, and permeability of the fabric are crucial factors. For instance, a heavier fabric might be required for steep slopes, while lighter ones suffice for flat areas. Look for documents testing the tensile strength. This ensures the fabric can endure significant stress during installation.

**Tip:** Always test a small section before a large installation. This helps assess the fabric's effectiveness in your specific environment.

Proper installation can affect performance. It’s vital to lay the fabric flat and avoid wrinkles. Wrinkles can trap water and lead to failure.

**Tip:** Review installation techniques and seek feedback from experienced users. Their insights can help avoid common mistakes.

Reflect on your choices. Sometimes, the cheaper option isn’t the best in the long run. Think about the project's longevity. Investing in quality materials often saves money and time later.

Choosing the right PP geotextile for your project hinges on understanding your specific requirements. Factors such as soil type, drainage needs, and load-bearing capacity must be assessed carefully. A detailed evaluation of these elements helps in narrowing down your options. For instance, coarse soils may require stronger, woven geotextiles, while finer soils might benefit from non-woven products that enhance filtration.

Additionally, consider the local climate and project duration. Projects exposed to harsh weather may require geotextiles with higher UV resistance. The thickness and weight of the fabric should also be evaluated based on expected load stresses. It’s important to reflect on the installation process too. Even a minor oversight here can lead to significant complications down the line. Ensuring compatibility with other materials used is crucial but often overlooked. A comprehensive understanding of these factors will significantly aid in selecting the best PP geotextile for your needs.

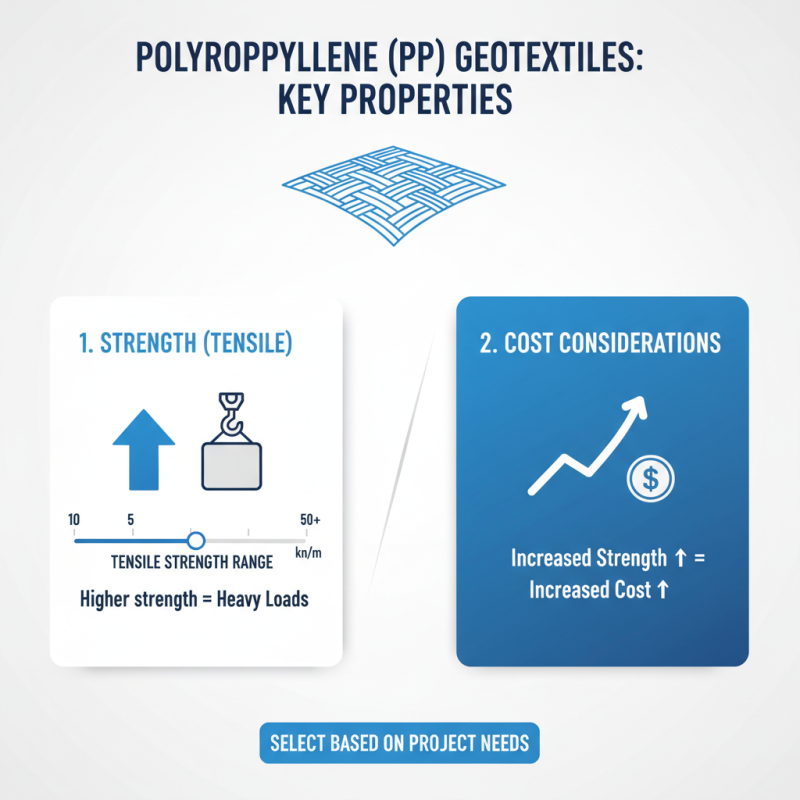

When selecting polypropylene (PP) geotextiles, key properties are crucial. Strength is a primary concern. Different projects require varying tensile strength. According to industry reports, tensile strength can range from 10 kN/m to over 50 kN/m. Higher strength is ideal for heavy loads, but it may increase costs.

Durability plays a significant role. PP geotextiles should withstand environmental stresses, including UV exposure and chemical reactions. Reports show that strong UV stabilization can extend the material's life to over 25 years. Yet, some geotextiles may degrade quickly in harsh conditions. Choosing the right type for specific environments is vital, but manufacturers often don’t provide enough data.

Permeability is another critical property. It dictates water flow through the geotextile. Too little permeability can lead to water retention, causing structural failures. Conversely, excessive permeability can allow soil washout. Technical specifications vary widely, so understanding the project's drainage needs cannot be overlooked. Balancing these strengths, durability, and permeability ensures proper function, yet many overlook detailed analysis in their selection process.

Choosing the right PP geotextile is crucial for the success of your project. Different types serve various purposes.

For drainage, non-woven geotextiles excel. They allow water to pass through while filtering soil particles.

This type is common in road construction and landscaping.

Conversely, woven geotextiles offer high tensile strength. They are ideal for applications requiring reinforcement.

They effectively separate soil layers and prevent mixing. This is vital in road and railway projects, where stability is key.

Selecting the wrong type can lead to project failure.

In some cases, the performance of a geotextile may fall short of expectations. It's worth considering the environmental impact too.

Proper assessment is necessary to avoid future issues. Always revisit your project requirements. Sometimes, the simplest choice is overlooked.

When sourcing polypropylene (PP) geotextiles, cost plays a crucial role. The price can vary greatly depending on the quality and supplier. It’s essential to gather multiple quotes from different manufacturers. This helps you understand the market better. Understand the key specifications needed for your project. Factors such as thickness, weight, and material type make a significant difference in pricing.

Another consideration is the potential for additional costs. Transportation fees can add up, especially for bulk orders. Sometimes suppliers have hidden fees, such as customs duties. Always read the fine print before committing. It's important to have a budget, but flexibility is key. Sometimes cheaper products might not meet your project needs. This could lead to unforeseen issues down the line.

Finally, engage with suppliers to gain insights. Ask about their production practices and certifications. Don't hesitate to negotiate terms. This can help manage costs effectively. Balancing quality and affordability is challenging. Take the time to reflect on your project's specific requirements. It will guide you in choosing the best PP geotextile for your needs.