Inquiry

Form loading...

- Phone

- E-mail

The construction industry faces increasing challenges. One of them is sustainability. "Geo Synthetic Material" offers a compelling solution. According to a report by the Global Geosynthetic Market, this sector is projected to reach $20.6 billion by 2026. This growth reflects a rising demand for innovative materials.

Geo synthetic materials enhance project efficiency. They provide excellent drainage, reinforcement, and separation. For instance, in road construction, these materials reduce soil erosion and improve stability. However, their initial cost can be a concern. Many still question the long-term benefits versus upfront expenses.

Despite some skepticism, Geo Synthetic Material shows promise. A significant portion of construction professionals recognizes its advantages. Yet, it’s essential to analyze their actual performance over time. The need for careful evaluation cannot be overstated. The industry's shift toward geosynthetics might be the future. Careful planning and understanding will make this transition smoother.

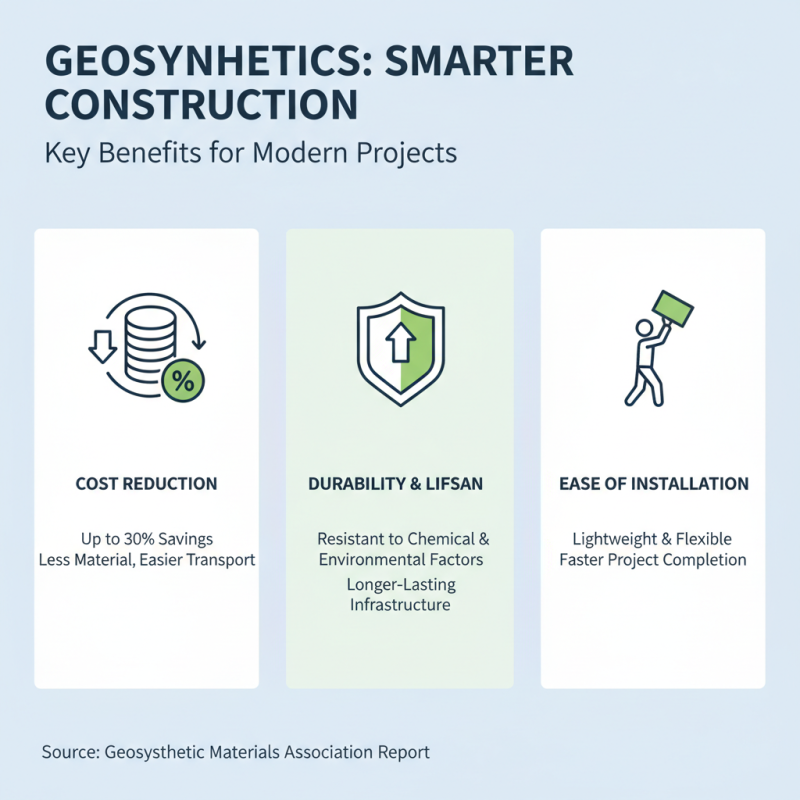

Geo synthetic materials are becoming increasingly popular in modern construction. Their benefits are significant. According to a report by the Geosynthetic Materials Association, these materials can reduce overall project costs by up to 30%. This savings stems from their durability and lightweight characteristics. They are easier to transport and install compared to traditional materials.

One notable advantage is their environmental impact. Geo synthetics can help control erosion, reduce runoff, and improve water management. According to the International Geosynthetics Society, they can lead to a 50% reduction in required fill material. This not only saves money but also decreases the carbon footprint of construction projects. However, there may be challenges, such as limited awareness and unfamiliarity among engineers regarding these materials.

Despite their benefits, some problems can arise. For instance, improper installation may lead to performance failures. It's crucial to ensure that teams are well-trained. These materials require specific handling procedures that must be followed. Continuous education and awareness within the industry are essential to overcome such hurdles.

Geo synthetic materials play a significant role in modern construction. Their diverse types offer solutions for various project needs. The main types include geo textiles, geo membranes, and geo grids. Each serves a unique purpose, ensuring durability and stability.

Geo textiles are fabric-based materials used for filtration, separation, and reinforcement. They help prevent soil erosion and enhance drainage. According to a report by the International Geosynthetics Society, the geo textiles market is expected to grow by over 10% annually. This reflects their increasing importance in infrastructure projects.

Geo membranes act as barriers, preventing water and contaminants from passing through. These materials are crucial in landfill and containment applications. Their effectiveness can reduce environmental risks significantly. Meanwhile, geo grids provide structural support to soil by distributing loads evenly. They are essential in road and pavement construction but can raise concerns about long-term durability.

Understanding the specifics of these materials is vital. Not all projects benefit equally from geo synthetics. The application must match the material type. Misuse can lead to failure and safety issues. Data shows that poor selection can increase project costs by 15-20%. It's a reminder to carefully evaluate project needs before choosing geo synthetic materials.

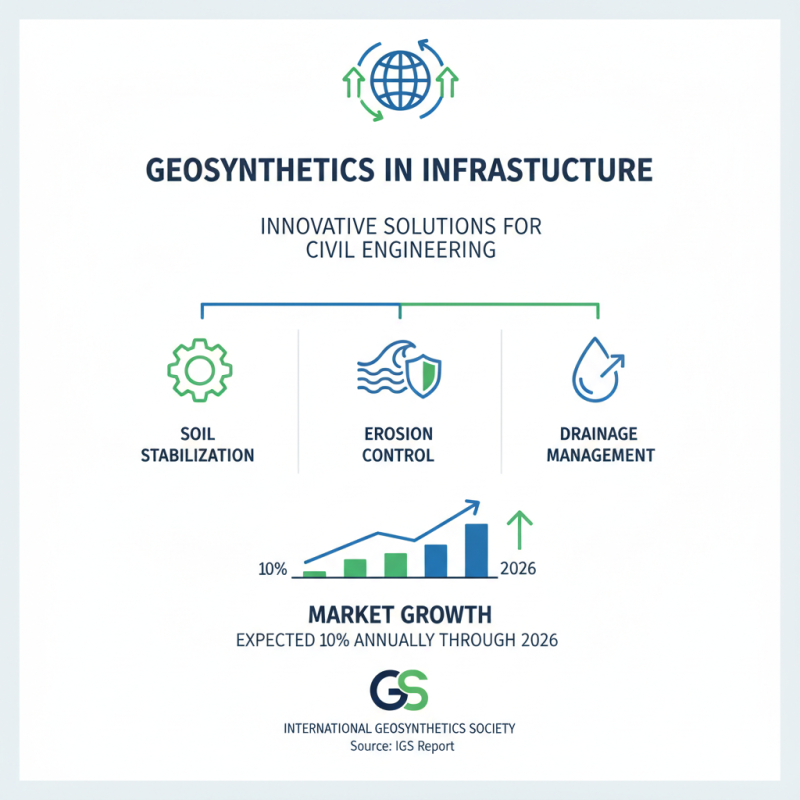

Geo synthetic materials have gained significant attention in infrastructure development. These innovative products offer solutions for soil stabilization, erosion control, and drainage management. A report by the International Geosynthetics Society indicates that the geo synthetic market is expected to grow by 10% annually through 2026. This growth highlights the increasing reliance on these materials in civil engineering projects.

Applications of geo synthetics are diverse and critical. For instance, they are used in road construction to reduce soil erosion. A study shows that using geo-textiles can decrease road maintenance costs by up to 30%. Geomembranes are also employed in landfill liners to prevent leachate contamination. Despite these benefits, some projects face challenges. Improper installation can lead to material failure. Engineers must consider environmental factors to ensure effectiveness.

In addition, the use of geo synthetics in retaining wall design has shown promising results. They provide structural support while minimizing the footprint of traditional materials. However, the learning curve for new technologies can be steep for some contractors. Overall, while geo synthetic materials present several advantages, careful planning and execution remain essential.

Geo synthetic materials have gained attention for their environmental benefits. These materials, made from polymers, offer sustainable solutions for various construction projects. Their lightweight nature reduces the energy needed for transport and installation. This is crucial in minimizing carbon footprints.

The durability of geo synthetic products contributes to their sustainability. They often require less maintenance, reducing long-term resource consumption. However, one must consider their disposal at the end of life. Improper handling can lead to environmental challenges. Many people overlook the fact that not all geo synthetics are biodegradable.

While geo synthetics can be beneficial, applying them requires careful planning. It's essential to evaluate how they interact with local ecosystems. Projects that use these materials should prioritize practices that protect the environment. Balancing construction needs with sustainability is an ongoing challenge, prompting questions about best practices in diverse contexts.

Geo synthetic materials are gaining traction in the construction industry due to their cost-effectiveness. These materials, including geotextiles and geomembranes, often reduce project costs. They can streamline processes and minimize labor needs. This leads to shorter timelines and less financial strain.

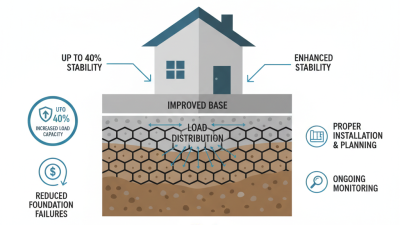

Using geo synthetic materials also offers long-term savings. They enhance the durability of structures. For instance, a geo synthetic layer can improve soil stability, which reduces maintenance costs over time. The initial investment may seem high. However, the reduced need for repairs makes it worthwhile. In some cases, it is essential to evaluate the suitability of these materials for specific projects.

While the benefits are evident, challenges exist. Not all projects may require geo synthetic materials. Misapplication can lead to failure. Proper research and planning are necessary before use. It's important to weigh the pros and cons carefully for optimal results.

| Material Type | Cost per Square Meter (USD) | Durability (Years) | Maintenance Requirement | Application Area |

|---|---|---|---|---|

| Geotextiles | $1.50 | 10-20 | Low | Road Construction, Drainage |

| Geomembranes | $2.00 | 20-30 | Minimal | Landfills, Water Containment |

| Geofoam | $8.00 | 50+ | Very Low | Lightweight Fill, Road Base |

| Geogrids | $3.50 | 20-25 | Moderate | Soil Reinforcement, Slopes |

| Geocells | $4.00 | 15-30 | Low | Erosion Control, Load Support |