Inquiry

Form loading...

- Phone

- E-mail

Selecting the right HDPE geomembrane for a project is a crucial task. The geomembrane is vital for soil containment and leak prevention. According to a report by the Geosynthetic Research Institute, improper selection can lead to failures, costing projects thousands in remediation. An expert in the field, Dr. John Smith, emphasizes, "Choosing the correct Geomembrana In Hdpe is essential for project longevity."

Various projects require specific properties from HDPE geomembranes. Factors such as thickness, strength, and chemical resistance play significant roles. For instance, a thicker membrane often provides better durability against punctures. However, thicker materials can be more challenging to handle and install, leading to potential complications during construction. This balance of properties is often overlooked, posing risks.

Additionally, real-world feedback from engineers shows inconsistencies in product performance. Some geomembranes may deliver well in testing but fail under actual conditions. It's a reminder that thorough evaluation and expert consultation are indispensable. Engaging with industry professionals can ensure that the selected Geomembrana In HdPE meets all project requirements, minimizing future issues.

HDPE geomembranes are critical in various applications. These plastic sheets are used for lining ponds, landfills, and other containment structures. They are made from high-density polyethylene, known for its durability and chemical resistance. This makes them suitable for preventing leaks in hazardous waste sites.

When choosing an HDPE geomembrane, consider the project requirements. Factors such as thickness, width, and flexibility are essential. Some projects may not need the thickest material. A thinner option might work just as well. Additionally, the installation process can affect the geomembrane's performance. Proper handling and laying are crucial to avoid damage.

It is also wise to reflect on the environmental impact. While HDPE geomembranes serve a purpose, they are made from fossil fuels. Recycling options exist, but they are limited. Projects should evaluate the trade-offs between function and sustainability. Overall, understanding the applications and limitations of HDPE geomembranes can lead to better decisions.

This bar chart illustrates the typical applications of HDPE geomembranes in various industries. The data represents the percentage of usage in different categories, providing insight into where HDPE geomembranes are most commonly utilized.

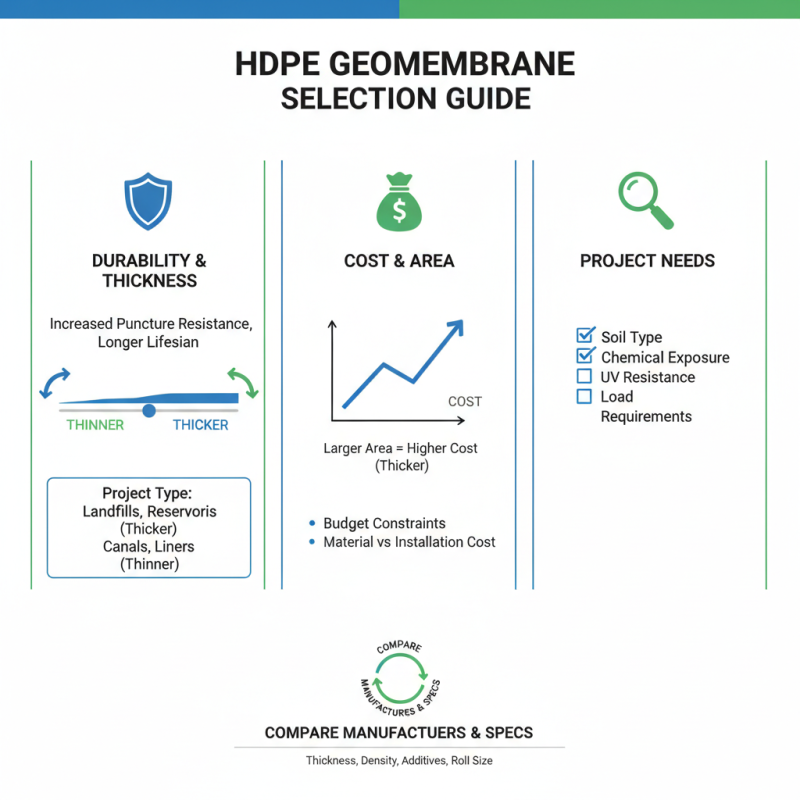

When selecting an HDPE geomembrane, evaluating project requirements is crucial. Understanding the environmental conditions is key. Studies indicate that around 30% of geomembrane failures stem from improper material selection. This highlights the importance of a thorough assessment.

Consider the project’s specific needs. Are you dealing with high moisture levels? A thickness of 60 mils or more may be necessary. In contrast, projects with lower risk might succeed with thinner geomembranes. A recent report showed that up to 40% of projects underutilize the appropriate thickness for their conditions, leading to premature failures.

Chemical resistance is another vital factor. Different projects expose geomembranes to various chemicals. According to industry research, nearly 25% of site applications fail to account for these variables. Gathering data on the chemicals involved is essential. This minimizes unexpected complications later. Evaluate these critical project aspects to choose the right HDPE geomembrane effectively.

| Project Type | Thickness (mm) | Color | UV Resistance | Chemical Resistance | Cost per Square Meter ($) |

|---|---|---|---|---|---|

| Landfill Liner | 2.0 | Black | Excellent | Good | 1.50 |

| Water Reservoir | 1.5 | Green | Good | Excellent | 1.30 |

| Mining Applications | 2.5 | Black | Excellent | Fair | 1.75 |

| Aquaculture | 1.0 | Blue | Good | Excellent | 1.20 |

| Construction | 1.2 | Black | Fair | Good | 1.40 |

Choosing the right HDPE geomembrane requires careful consideration of key properties. First, think about thickness. Thicker membranes typically offer better resistance. However, they can be heavier and harder to install. Balancing durability and manageability is crucial.

Next, look at tensile strength. This property determines how well the membrane can handle stress without breaking. A higher tensile strength means more robust performance over time. Additionally, consider puncture resistance. A geomembrane with good puncture resistance helps prevent leaks and damage from sharp objects.

Finally, evaluate UV resistance. Exposure to sunlight can degrade materials. A geomembrane with UV stabilization will last longer, especially in outdoor projects. Take into account the specific conditions of your project site, as these factors can greatly influence the lifespan and effectiveness of the geomembrane.

When choosing an HDPE geomembrane, it is crucial to compare various manufacturers and their product specifications. One important factor is the thickness of the geomembrane. Different projects may require different thicknesses. A thicker sheet may offer better durability but can be cost-prohibitive for larger areas. Understanding the specific needs of your project is vital.

Chemical resistance is another key aspect to consider. Some manufacturers use different additives that improve performance in harsh environments. This variation can affect the geomembrane's lifespan and maintenance needs. It's wise to check test results for compatibility with the specific chemicals in your project.

Additionally, consider the installation process. Some geomembranes are easier to install than others. This can lead to faster project completion and lower labor costs. However, not all easy-to-install products guarantee quality. Evaluate feedback from past projects carefully. Each manufacturer has unique strengths and weaknesses, and understanding these can lead to more informed decisions.

When installing HDPE geomembranes, it’s crucial to consider the environment. Proper site preparation is essential. Clear the area of debris and sharp objects. This helps prevent punctures during installation. The surface should be relatively smooth. Uneven terrain can cause stress points.

Temperature also plays a vital role. HDPE materials can expand and contract. Installing in extreme temperatures may compromise integrity. It's recommended to schedule installation in moderate conditions. Monitor wind speeds, too. High winds can move the material, reducing precision.

Maintenance is equally important. Regular inspections help identify issues early. Look for signs of wear or damage. Repair any gaps as soon as possible. Water accumulation can lead to problems down the line. Check drainage systems frequently. A proactive approach minimizes long-term costs.