Inquiry

Form loading...

- Phone

- E-mail

When it comes to selecting the right HDPE geomembrane for your project, understanding the nuances of this essential material is critical. According to Dr. Emily Johnson, a leading expert in the field of geosynthetics, "Choosing the appropriate HDPE geomembrane can significantly influence the durability and success of environmental containment projects." With a variety of factors to consider, including thickness, manufacturer specifications, and installation protocols, making an informed decision is paramount.

The HDPE geomembrane is widely recognized for its resilience and effectiveness in managing liquid containment, including waste management and environmental protection applications. As developments in technology continue to advance, the options available for HDPE geomembranes also expand, further complicating the selection process. To ensure that your project meets its specific needs while adhering to industry standards, careful evaluation of the different available products and their appropriate applications is essential.

This guide aims to provide comprehensive insights into the selection criteria for HDPE geomembranes, helping you navigate through the available choices with confidence. By equipping yourself with knowledge about the material's properties and best practices, you can ensure optimal performance in your upcoming projects.

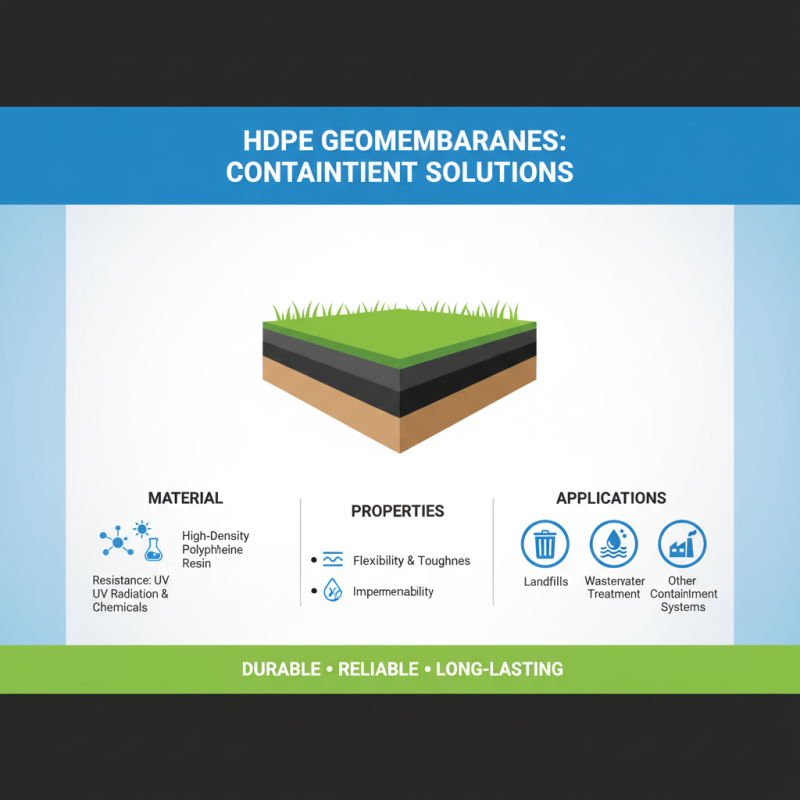

HDPE geomembranes, or high-density polyethylene geomembranes, are widely used in containment applications due to their unique materials and properties. Made from high-density polyethylene resin, these geomembranes offer excellent resistance to environmental stressors, including ultraviolet radiation and chemical exposure. This makes them a preferred choice for landfills, wastewater treatment facilities, and other containment systems that require long-lasting durability. The flexibility and toughness of HDPE geomembranes allow them to adapt to various installation conditions while maintaining impermeability.

One of the defining characteristics of HDPE geomembranes is their low permeability, which is crucial for preventing the migration of liquids and gases. With a permeability rate often less than 1 x 10^-11 cm/sec, they are highly effective in minimizing leakage. Additionally, HDPE geomembranes can be produced in a range of thicknesses, typically from 0.5mm to 2.5mm, allowing project managers to select the right level of protection based on their specific needs. Furthermore, the material can withstand high temperatures, making it suitable for a variety of climates and conditions. Understanding these properties is essential for stakeholders to make informed decisions about integrating HDPE geomembranes into their project designs.

When selecting the right HDPE geomembrane for your project, several key considerations come into play. First and foremost, understanding the specific application is crucial. HDPE geomembranes are commonly used for environmental containment, such as in landfills, mining operations, and water management systems. The environmental conditions, including exposure to chemicals and temperature fluctuations, will directly influence the choice of geomembrane. It's essential to evaluate the compatibility of the geomembrane material with the site’s operational requirements and anticipated environmental stresses.

Another critical factor is the thickness and tensile strength of the geomembrane. Thicker geomembranes typically offer greater durability and resistance to punctures, making them suitable for more demanding applications. However, this can also affect the ease of installation and cost. Furthermore, reviewing the ease of installation and the potential need for additional accessories, such as sealing systems or drainage layers, can impact the overall effectiveness of the geomembrane in fulfilling its intended purpose. By carefully assessing these factors, you can make a more informed decision that aligns with your project's specific needs.

When selecting the appropriate high-density polyethylene (HDPE) geomembrane for a specific project, two critical factors stand out: thickness and flexibility. The thickness of an HDPE geomembrane directly impacts its durability and resistance to punctures and tears. Thicker geomembranes typically offer enhanced protection against environmental stresses, making them suitable for applications where high resistance to potential damage is required, such as in landfill liners and containment structures.

On the other hand, flexibility is equally essential in ensuring that the geomembrane can accommodate ground movement and variations in terrain. A flexible geomembrane allows for easier installation and adaptability to irregular surfaces, reducing the risk of wrinkles or stress points that could compromise its integrity. When comparing different HDPE geomembranes, it is crucial to find a balance between thickness and flexibility, as each project has unique demands. In applications requiring high durability without sacrificing the ability to conform to the subgrade, opting for a geomembrane with moderate thickness combined with superior flexibility may be the most effective choice.

| Thickness (mm) | Maximum Flexibility (mm) | Typical Applications | Key Benefits |

|---|---|---|---|

| 0.5 | 30 | Pond Liners, Large Tanks | Lightweight, Cost-effective |

| 0.75 | 25 | Landfills, Waste Containment | Enhanced Puncture Resistance |

| 1.0 | 20 | Water Reservoirs, Civil Engineering Projects | Durable, Long-lasting |

| 1.5 | 15 | Barrier Walls, Chemical Storage | Excellent Chemical Resistance |

| 2.0 | 10 | Mining Applications, Large-Scale Liners | High Strength, Thick Design |

When evaluating the installation methods for HDPE geomembranes, it is crucial to consider the specific needs of your project alongside the environmental conditions and expected performance of the material. According to a report by the Geosynthetic Institute, proper installation techniques can significantly enhance the longevity and functionality of HDPE geomembranes, which are fabricated from high-density polyethylene. Various methods such as fusion welding and extrusion welding are often employed, with the industry standards suggesting that fusion welding, in particular, provides superior seam strength, often exceeding the tensile strength of the geomembrane itself.

Additionally, the choice of installation method can affect the project's overall cost and efficiency. The United States Environmental Protection Agency (EPA) notes that improper handling and installation can lead to defects, which might compromise the geomembrane's integrity, leading to potential project failures. Notably, the National Geosynthetic Research Committee emphasizes that following established guidelines and employing skilled technicians can mitigate risks associated with improper installation techniques, ensuring that the geomembrane achieves its designed life span, which can extend up to 30 years or more under optimal conditions. Understanding these factors is vital for selecting the right geomembrane installation method tailored to your specific project requirements.

When selecting the right HDPE geomembrane for a project, assessing environmental conditions is critical for ensuring optimal performance. According to a report by the Geosynthetics Institute, environmental factors such as temperature variations, chemical exposure, and UV radiation can significantly affect the lifespan and integrity of geomembranes. For example, HDPE geomembranes are known to endure a wide range of temperatures, from -30°C to 60°C, making them suitable for various climates. However, prolonged exposure to extreme temperatures can lead to degradation, making it essential to analyze the specific temperature ranges anticipated during the project's lifecycle.

Beyond temperature, chemical resistance is a vital consideration. The American Society for Testing and Materials (ASTM) emphasizes the importance of understanding the specific chemicals that the geomembrane will encounter in its intended application. HDPE geomembranes exhibit excellent resistance to a variety of harsh chemicals, but their performance can vary significantly by exposure duration and concentration levels.

A detailed chemical compatibility chart can help project managers make informed decisions, ensuring that the selected geomembrane can withstand the specific environmental conditions without compromising its structural integrity over time. Through careful assessment of these factors, project managers can enhance not only the performance of the geomembrane but also the overall success of their projects.