Inquiry

Form loading...

- Phone

- E-mail

Selecting the right HDPE geomembrane for your project is crucial to ensuring effective containment and environmental protection. High-Density Polyethylene (HDPE) geomembranes are commonly used barriers in various applications, including landfill liners, water reservoirs, and mining operations. With a wide variety of products available on the market, understanding the specific needs of your project is essential to make an informed choice.

In this introduction, we will explore the key factors to consider when choosing an HDPE geomembrane, such as thickness, textured vs. smooth surface, and compatibility with the substances being contained. By carefully assessing these criteria, project managers can enhance the durability and performance of geomembrane systems, minimizing potential risks and ensuring compliance with environmental regulations. Whether it is for a construction site or a long-term waste management application, the correct selection of an HDPE geomembrane can significantly impact the project's success and sustainability.

HDPE (High-Density Polyethylene) geomembranes are becoming increasingly essential in various industry applications due to their durability, chemical resistance, and cost-effectiveness. As a flexible barrier, HDPE geomembranes are widely used in landfill lining, mining operations, and water containment systems. According to a report by Research and Markets, the global geomembrane market size is projected to reach $4.2 billion by 2026, highlighting the growing need for effective containment solutions.

When choosing the right HDPE geomembrane for your project, it's crucial to consider the specific characteristics of your application. Factors such as thickness, UV resistance, and tensile strength must be evaluated to ensure the geomembrane meets project requirements. For instance, a typical HDPE geomembrane ranges from 0.5 mm to 2.5 mm in thickness, depending on the project’s demands. Additionally, industry standards, such as those set by ASTM International, provide guidelines on material specifications to ensure the reliability and performance of geomembranes in various environments.

**Tips:** Always consult with a certified engineer to assess the soil and environmental conditions of your project site. Additionally, utilizing a geomembrane with a higher UV resistance can significantly extend the life of the installation, especially in harsh climates.

Choosing the right HDPE geomembrane also involves evaluating installation requirements and ensuring that the selected material aligns with budget constraints. For more significant projects, consider utilizing geosynthetic materials alongside HDPE geomembranes to enhance the overall stability and efficiency of containment systems. It's essential to factor in the long-term benefits of using high-quality materials, as they can lead to lower maintenance costs and increased durability over time.

**Tips:** Review case studies or industry reports to understand how similar projects approached their geomembrane selection and installation. This can offer invaluable insights into best practices and potential challenges.

| Project Type | HDPE Thickness (mm) | Key Applications | Environmental Resistance | Cost (per square meter) |

|---|---|---|---|---|

| Landfill Liner | 1.5 | Waste Containment | Chemical, UV | $1.20 |

| Mining Waste Pond | 2.0 | Tailings Storage | Acid, UV | $1.50 |

| Agricultural Pond | 0.75 | Water Storage | UV, Algae | $0.80 |

| Civil Construction | 1.0 | Drainage Solutions | Water, Chemical | $1.00 |

| Aquaculture | 1.0 | Fish Farming | UV, Fish Safe | $1.10 |

When selecting the right HDPE geomembrane for your project, understanding the key project requirements is essential to ensure optimal performance and longevity. One of the primary considerations is the specific environmental conditions in which the geomembrane will be installed. According to a report by the Geosynthetic Research Institute, approximately 40% of geomembrane failures are attributed to inadequate consideration of environmental stressors such as UV exposure, temperature fluctuations, and physical abrasion. Analyzing these factors can help you determine the appropriate thickness and type of HDPE material needed to withstand your project's unique challenges.

Another critical requirement is the compatibility of the geomembrane with the materials it will be in contact with, such as soil, water, and waste. Studies indicate that improper material compatibility can lead to chemical degradation, significantly shortening the lifespan of the geomembrane. The United States Environmental Protection Agency (EPA) data shows that a compatible geomembrane can enhance service life by over 15 years compared to those in incompatible environments. Conducting thorough compatibility testing and a comprehensive risk assessment can guide you in selecting the correct product that meets both hydraulic and chemical resistance needs in your specific application, be it landfill liners or containment systems.

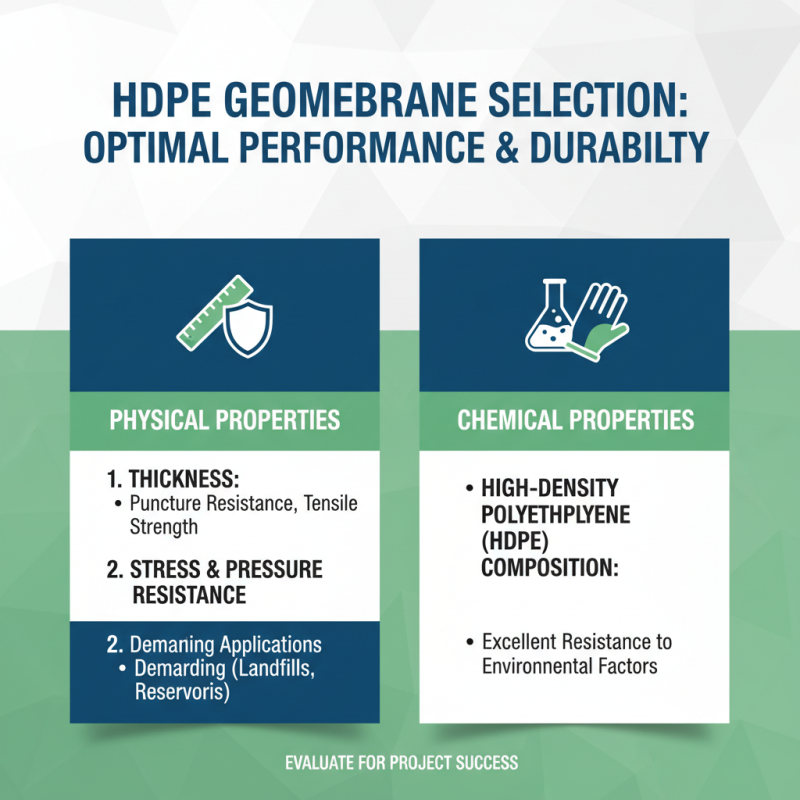

When selecting the right HDPE geomembrane for your project, it's crucial to evaluate its physical and chemical properties to ensure optimal performance and durability. HDPE geomembranes are widely recognized for their high-density polyethylene composition, which offers excellent resistance to various environmental factors. The thickness of the geomembrane is a primary physical property to consider, as it influences the material’s ability to withstand stress and pressure. Thicker membranes provide greater puncture resistance and tensile strength, making them suitable for more demanding applications, such as landfill liners and reservoirs.

In addition to physical attributes, the chemical resistance of HDPE geomembranes plays a vital role in their applicability across various projects. HDPE is known for its exceptional resistance to a wide range of chemicals, including acids, bases, and hydrocarbons, making it ideal for industrial applications. Evaluating the chemical compatibility of the geomembrane with the substances it will encounter is essential to prevent material degradation over time. Moreover, understanding the temperature tolerance and potential for UV exposure will further aid in selecting a geomembrane that can maintain its integrity in varying environmental conditions. Making informed decisions based on these properties will ultimately lead to a successful project outcome.

When selecting the appropriate HDPE geomembrane for your project, understanding the differences in thickness and weight is crucial. HDPE geomembranes are available in a variety of thicknesses, typically ranging from 20 to 120 mils. Thicker geomembranes generally offer enhanced puncture resistance and durability, making them suitable for high-stress applications, such as mining and landfill liners. According to a report by the Geosynthetic Research Institute, the puncture resistance increases significantly with each incremental increase in thickness, often cited at nearly a 10% increase per 10 mils of thickness.

Weight is another essential factor that influences performance. HDPE geomembranes can vary in weight based on their thickness and specific density. For instance, a 60 mil geomembrane may weigh approximately 0.75 lbs per square foot, while an 80 mil version might weigh around 1 lb per square foot. This difference can impact installation procedures and the overall structural integrity of your project. Understanding the project’s environmental conditions and mechanical stress expectations is essential to selecting the right combination of thickness and weight, ensuring long-term effectiveness and reliability in containment applications.

When selecting HDPE geomembranes for specific projects, it's crucial to assess both the installation methods and long-term performance. The installation process can significantly influence the effectiveness and durability of geomembranes. Techniques such as jointing, welding, and the proper placement of the membrane must be carefully evaluated. Proper training for installation crews and adherence to best practices ensure that the geomembrane achieves optimal sealing and minimizes the risk of leaks. On-site conditions, including temperature, weather patterns, and substrate preparation, must also be taken into account to enhance successful installation.

Long-term performance of HDPE geomembranes is determined by several factors, including material properties, environmental exposure, and maintenance practices. HDPE is known for its resistance to UV radiation, chemical exposure, and punctures; however, ongoing monitoring and maintenance are essential to maximize its lifespan. Projects should incorporate regular inspections and maintenance schedules to identify and address potential issues before they escalate. Understanding these aspects helps project managers select the most suitable HDPE geomembrane, ensuring that the installation method aligns with the specific environmental challenges and project requirements for lasting performance.