Inquiry

Form loading...

- Phone

- E-mail

In the competitive landscape of plastic manufacturing, the demand for HDPE (High-Density Polyethylene) plastic sheets has seen substantial growth, projected to reach a market value of approximately $40 billion by 2025, according to a recent industry report. As global buyers seek durable and versatile materials for various applications, understanding the nuances of HDPE plastic sheets becomes vital. This ultimate guide not only compares the top HDPE plastic sheets available on the market but also delves into the advantages of after-sales services and maintenance costs. With insight into industry standards and expert tips, this comprehensive analysis aims to equip buyers with the knowledge needed to make informed decisions while navigating the diverse offerings of HDPE plastic sheets.

HDPE plastic sheets, made from high-density polyethylene, have become a popular choice across various industries due to their exceptional properties and benefits. One of the standout features of HDPE is its impressive strength-to-density ratio. This material is not only lightweight but also remarkably durable, making it ideal for applications ranging from packaging to construction. Its resistance to impact and abrasions ensures long-lasting performance, reducing the need for frequent replacements. Moreover, HDPE sheets are resistant to many chemicals, which makes them suitable for use in environments that require frequent exposure to harsh substances.

Another significant advantage of HDPE plastic sheets is their ability to withstand various weather conditions. They are UV-stabilized, ensuring that they won’t degrade or lose their structural integrity when exposed to sunlight for extended periods. Additionally, these sheets are inherently moisture-resistant, making them less prone to warping or mildew, which is crucial for outdoor applications. The ease of fabrication also adds to their appeal; HDPE can be easily cut, welded, and shaped to meet specific design needs. This versatility coupled with its environmental benefits, as it can be recycled multiple times, positions HDPE sheets as a sustainable option for global buyers looking for reliable materials.

This chart compares key properties of HDPE plastic sheets, including thickness, density, tensile strength, elongation, and temperature resistance. Each property is crucial for understanding the material's applications and performance in various industries.

When comparing HDPE (High-Density Polyethylene) plastic sheets, several key factors should be taken into account to ensure you select the right material for your needs. First and foremost, consider the thickness of the sheets. Thicker sheets generally offer greater durability and impact resistance, making them suitable for heavy-duty applications. Conversely, if weight and flexibility are major concerns, thinner sheets might be more appropriate. Additionally, pay attention to the sheet size, as larger dimensions can reduce waste and simplify installation in extensive projects.

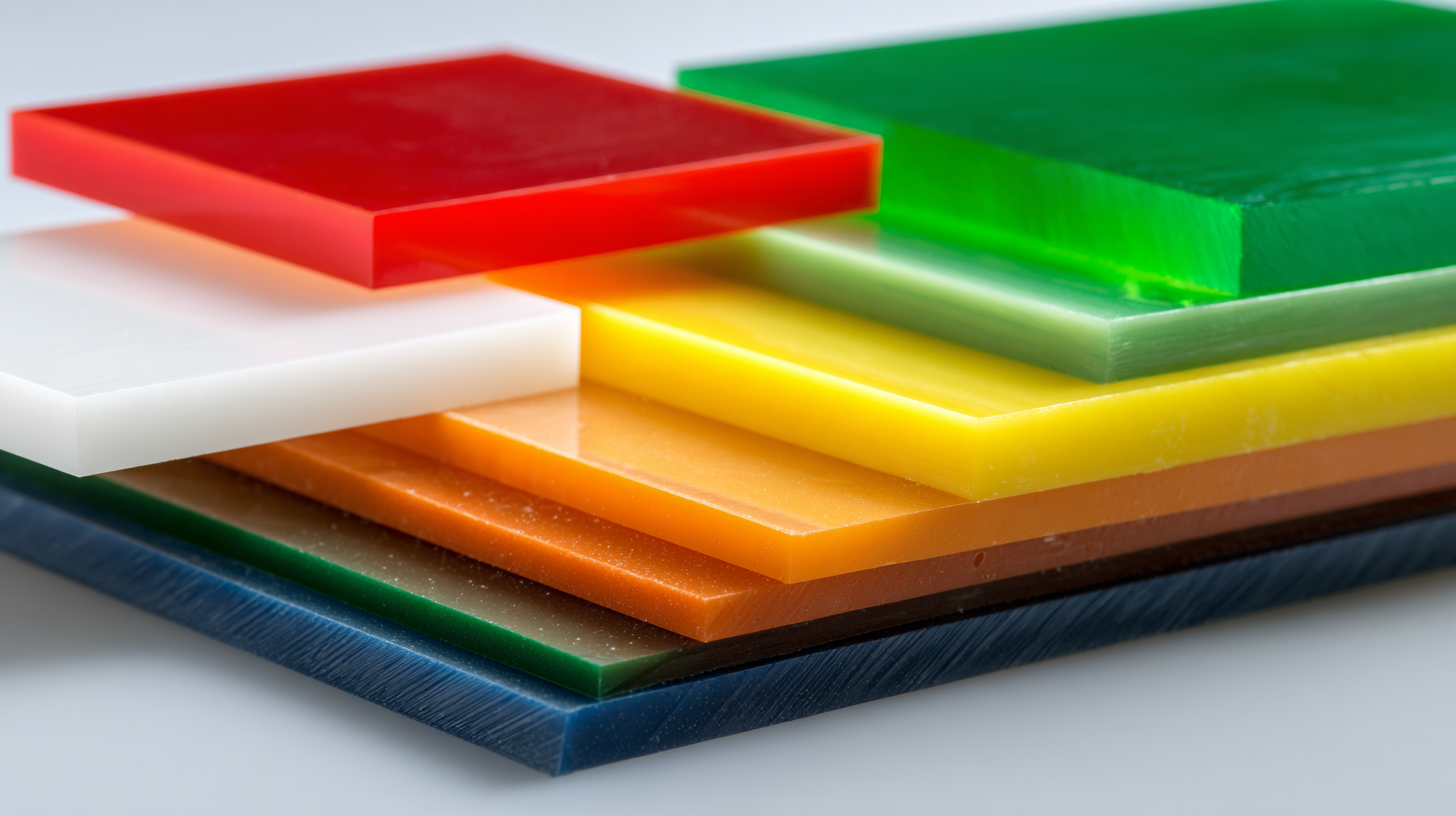

Another crucial factor is the surface finish of the HDPE sheets. Different finishes, such as textured or smooth surfaces, can affect both aesthetic appeal and functionality. A textured surface may provide better grip in applications like flooring or food preparation, while a smooth finish is often easier to clean and maintain. Furthermore, examine the color options available, as HDPE sheets come in a variety of colors that can influence the end-use, such as UV stabilization for outdoor settings. Finally, evaluating the manufacturer’s reputation and ensuring compliance with industry standards will help ensure the quality and longevity of the sheets.

When exploring the market for HDPE plastic sheets, it's essential to recognize the top global manufacturers driving innovation and meeting the growing demand. The HDPE industry is witnessing a significant upward trend, with the global high-density polyethylene resins market size projected to increase from $52.39 billion in 2019 to an estimated $68.30 billion by 2027, reflecting a compound annual growth rate (CAGR) of 4.96%. This growth is largely driven by the ongoing recovery in various economies and the heightened application of HDPE in sectors like packaging, construction, and agriculture.

As you compare the leading manufacturers of HDPE sheets, consider the expanding polyethylene films packaging market, expected to grow from USD 98.47 billion in 2024 to around USD 139.98 billion by 2032. This market expansion indicates not only the versatility of HDPE but also the importance of selecting suppliers that keep pace with technological advancements and sustainability practices.

**Tips:** When choosing HDPE sheets, assess manufacturers on the basis of their customer service, product quality, and sustainability initiatives. Ensure they comply with industry regulations and standards for a reliable purchasing experience. Additionally, stay updated on market trends to make informed decisions about your suppliers.

HDPE plastic sheets have become increasingly popular across various industries due to their remarkable durability, chemical resistance, and versatility. One of the key applications of HDPE sheets is in the construction industry, where they serve as moisture barriers and protective surfaces. Their resistance to impact and weathering makes them ideal for outdoor applications, including roofing and wall cladding. Additionally, HDPE sheets are often used in the manufacturing of containers, tanks, and pipes, making them essential for water and wastewater management.

In the food industry, HDPE sheets are widely utilized for their non-toxic and easy-to-clean properties. They are commonly found in cutting boards, food storage containers, and even conveyor belts within processing plants. The medical field also benefits from HDPE's sterile qualities, using it for medical devices, packaging, and laboratory equipment. Furthermore, the agricultural sector employs HDPE sheets for various purposes such as lining for ponds, greenhouses, and protective covers, illustrating the versatility of this material in enhancing productivity and safety across different fields.

When evaluating HDPE plastic sheets, understanding the cost is crucial for global buyers looking to make informed purchasing decisions. The price of HDPE sheets can vary significantly based on factors such as thickness, size, and manufacturer. Conducting a thorough cost analysis helps buyers assess the value of these products in relation to their specific needs. Comparing prices from different suppliers and considering bulk purchasing options can lead to significant savings.

**Tips:** Always check for additional costs, such as shipping and handling, as these can affect the overall price. Look for suppliers who offer warranties or guaranties on their products, as this can be an indicator of quality and reliability. Additionally, don’t overlook the importance of customer reviews; insights from other buyers can provide valuable information about the longevity and performance of the sheets you’re considering.

Another vital aspect of cost analysis is the potential return on investment. HDPE sheets are known for their durability and resistance to various environmental factors, which can result in lower maintenance and replacement costs. By calculating the long-term savings, buyers can justify the initial expenditure and make wiser choices when it comes to selecting the right HDPE sheets for their projects.

| Sheet Thickness (mm) | Color Options | Size (ft²) | Cost per Sheet (USD) | Durability (Years) |

|---|---|---|---|---|

| 3 | Black, White, Blue | 4x8 | 45.00 | 10 |

| 6 | Green, Yellow | 4x10 | 60.00 | 15 |

| 12 | Black, White, Blue, Green | 5x8 | 120.00 | 20 |

| 20 | White, Blue | 4x12 | 250.00 | 30 |