Inquiry

Form loading...

- Phone

- E-mail

Geo Grid Mesh applications are transforming the landscape of engineering and construction. These innovative materials provide essential support for various projects, enhancing stability and efficiency. Mastering Geo Grid Mesh techniques can significantly improve the durability of structures like roads, slopes, and retaining walls.

The use of Geo Grid Mesh helps in distributing load more evenly. It minimizes erosion and stabilizes the soil effectively. However, using these materials requires careful consideration. Mistakes in installation can lead to project failures or increased costs. Understanding the properties of Geo Grid Mesh is crucial.

Explore the nuances of these applications as you dive deeper into the methods and strategies. This guide offers practical tips on achieving optimal results while using Geo Grid Mesh. Embrace the challenges and learn from any errors; every project is an opportunity for growth and improvement.

Geo grid mesh plays a crucial role in modern civil engineering. It's essential for reinforcing soil and improving stability. This mesh is used in various applications like road construction and retaining walls. Properly understanding these applications can lead to better outcomes in engineering projects.

Key concepts include tension and load distribution. Geo grids help to distribute loads evenly, reducing stress on soil. They are often used to enhance the bearing capacity of weak soils. However, engineers must consider soil characteristics carefully. Not all soils respond the same way to reinforcement.

When selecting the right geo grid mesh for your project, it’s crucial to understand your specific requirements. Geo grids are used extensively in construction and civil engineering. They enhance the stability and strength of soil. According to industry reports, choosing the right material can reduce project costs by up to 30%.

Focus on the type of project. Are you working on road construction, embankments, or retaining walls? Each scenario demands different mesh specifications. Consider strength, durability, and environmental factors. A wrong choice can lead to failures, adding more expenses than anticipated.

Tip: Analyze your soil conditions before selection. Different soils have unique traits, affecting geo grid performance. Perform tests to determine soil behavior under load. Another critical factor is the mesh aperture and weight. Ensure it aligns with your project’s load requirements. Often overlooked, proper installation is key. Poor installation can compromise even the best geo grid mesh.

| Tip # | Tip Description | Application Area | Material Type | Recommended Thickness (mm) |

|---|---|---|---|---|

| 1 | Assess soil properties before selection. | Foundations | Polypropylene | 3-5 |

| 2 | Choose the right grid aperture size. | Roads & Pavements | High-Density Polyethylene | 4-6 |

| 3 | Consider environmental conditions. | Erosion Control | Fiberglass | 2-4 |

| 4 | Evaluate load requirements. | Reinforced Areas | Geosynthetics | 5-7 |

| 5 | Incorporate proper drainage. | Slope Stabilization | Bentonite | 3-5 |

Geo grid mesh applications are crucial for enhancing soil stability in various construction projects. Proper installation techniques can significantly impact the effectiveness of these solutions. Research shows that if geo grid is installed incorrectly, it can reduce performance by up to 40%. Understanding the terrain and soil conditions is vital before beginning installation.

When laying the geo grid, ensure it is tensioned correctly. This helps to distribute loads more evenly. A study indicated that improperly tensioned grids can lead to soil failure areas. It's essential to compact the subgrade thoroughly before installation. This preparation step often gets overlooked but is key to preventing future issues. Use lightweight rollers if the site has access restrictions.

Pay attention to overlaps during installation. Overlapping sections should be at least one foot. This is often neglected, leading to reduced strength at critical points. Monitoring weather conditions pre-installation is another detail worth considering. Rain can weaken soil, making it less suitable for geo grid applications. By keeping these factors in mind, the long-term performance of geo grids can continuously improve.

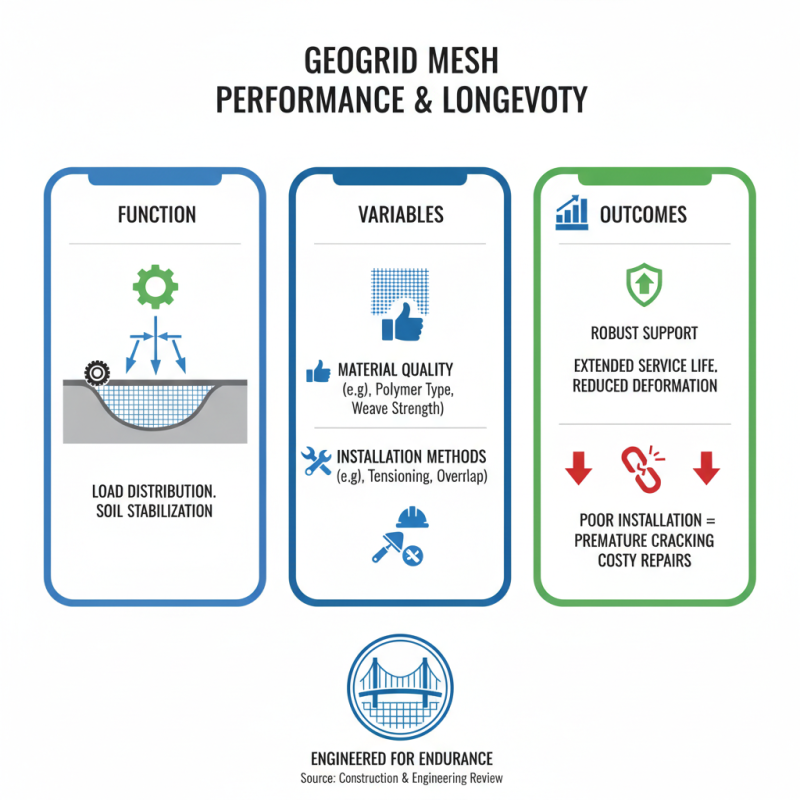

Evaluating the performance and longevity of geo grid mesh structures is essential in construction and engineering. These products provide strong support, but their effectiveness can vary based on material quality and installation methods. For instance, a poorly installed geo grid can lead to significant long-term issues. The mesh should ideally distribute loads evenly to avoid points of failure.

The mesh's lifespan depends on several factors. Environmental conditions, such as temperature and moisture, play a role. Too much water or extreme temperatures can degrade the material over time. Regular inspections are vital. Noticing early signs of wear can prevent major failures. It’s not uncommon for structures to fail due to oversight in maintenance checks. Adopting a proactive approach ensures better reliability and longevity for geo grid applications.

In the realm of geo grid mesh applications, several challenges commonly arise. One major issue is soil compatibility. Research from the Geosynthetic Institute indicates that nearly 40% of failures in geo grid applications stem from improper soil selection. Understanding soil types is crucial. Different soils react differently to stress and load. Engineers must conduct thorough site assessments before applying geo grids.

Another prevalent challenge is installation errors. Misalignment during installation can lead to significant structural weaknesses. A study from the Federal Highway Administration reported that up to 30% of geo grid projects faced issues due to installation mistakes. Attention to detail is vital. Proper training for installation crews can mitigate these errors. Many projects overlook the importance of continuous quality checks, which can catch potential problems early on.

Water management also poses a significant challenge. Inadequate drainage can lead to long-term degradation of geo grid efficacy. Almost 25% of geo grid failures are attributed to poor drainage solutions, as highlighted by the International Geosynthetics Society. Engineers should prioritize effective drainage systems. Incorporating additional features such as weep holes can enhance performance. Each of these challenges illustrates the nuances involved in successful geo grid mesh applications.

This chart highlights the common challenges encountered in Geo Grid Mesh applications, rated on a scale from 1 to 10 based on severity. Understanding these challenges can help in developing effective solutions and mastering Geo Grid Mesh technologies.