Inquiry

Form loading...

- Phone

- E-mail

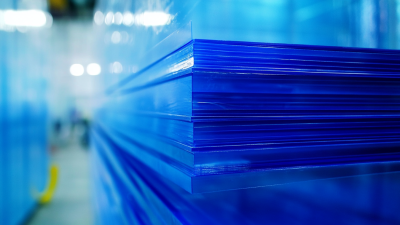

In recent years, the demand for high-density polyethylene (Hdpe Sheet) has surged, driven by its versatile applications across various industries, including construction, packaging, and environmental management. According to a 2021 report by Grand View Research, the global HDPE market size was valued at approximately $80 billion, with expectations of significant growth as industries increasingly prioritize sustainability and lightweight materials.

As manufacturers respond to evolving market trends, it is crucial for buyers to stay informed about the latest advancements and options available. This article presents five expert tips to help you navigate the selection process and choose the best Hdpe Sheet tailored to your specific needs, ensuring you make an informed decision based on current market dynamics. By understanding the varied properties and applications of Hdpe Sheets, you can leverage industry insights to optimize your purchasing choices effectively.

When selecting the best HDPE (High-Density Polyethylene) sheets, it's essential to understand their key properties that can significantly impact your application. HDPE sheets are known for their durability, chemical resistance, and low moisture absorption, making them suitable for a variety of industries, from packaging to construction. Assessing the thickness and density of the sheets can also influence their performance. Thicker sheets offer greater strength and impact resistance, while density can affect flexibility and rigidity, crucial factors depending on your intended use.

To make an informed choice, consider market trends that highlight the demand for recycled HDPE sheets. With sustainability on the rise, opting for eco-friendly materials can not only enhance your brand image but also reduce costs. Additionally, consult with suppliers about custom fabrication options for unique applications, which can transform a standard sheet into a tailored solution that meets specific operational needs. Keep these insights in mind as you navigate the HDPE sheet market, ensuring you select the right material for your project's success.

The demand for High-Density Polyethylene (HDPE) sheets is significantly influenced by several key market trends that are reshaping various industries. According to a report by MarketsandMarkets, the global HDPE market is expected to grow from USD 66.11 billion in 2021 to USD 94.42 billion by 2026, at a CAGR of 7.3%. This surge is driven by the rising utilization of HDPE sheets in packaging, construction, and automotive sectors due to their durability and resistance to impact and chemicals.

One of the primary factors accelerating this demand is the push towards sustainable materials and eco-friendly products. The increasing emphasis on recycling and the use of recyclable materials is leading to expanded applications for HDPE sheets in the manufacturing of reusable containers and eco-conscious products. Additionally, the construction industry's recovery post-pandemic, coupled with continuous advancements in product design, is fostering a greater uptake of HDPE sheets. A recent Grand View Research report indicates that the construction segment held over 30% of the overall market share in 2022, highlighting the pivotal role that infrastructural developments play in driving HDPE sheet consumption.

When it comes to selecting the right HDPE sheet for your specific needs, understanding the thickness is crucial. The thickness of the HDPE sheet can significantly impact its durability, flexibility, and suitability for various applications. If you’re unsure about how thick your sheets should be, consider evaluating your project's requirements—whether it's something that needs to be lightweight for easy handling or robust for heavy-duty use.

One expert tip is to assess the environmental factors your HDPE sheet will encounter. For example, applications exposed to harsh weather conditions may benefit from thicker sheets to ensure longevity and performance. Additionally, think about the type of load the sheet will bear. A thicker sheet might be necessary for heavy loads, while a thinner sheet could suffice for lighter applications.

Lastly, it's essential to consider market trends. Keeping an eye on industry shifts can inform you about popular thickness ranges that others are choosing for comparable applications. This information can guide you in making an informed decision, ensuring you not only pick a product that meets your immediate needs but also one that aligns with broader market practices.

When selecting HDPE sheets, it's essential to focus on sustainability factors, given the current market trends surrounding plastic use and its environmental impact. With the rise of plastic pollution and the need for eco-friendly solutions, choosing HDPE options that are manufactured sustainably can make a significant difference. Ensure that the products you consider are sourced from recycled materials or produced with minimal waste and energy consumption.

Moreover, evaluate the lifecycle of the HDPE sheets. Investigate their end-of-life disposal methods, as improper disposal can exacerbate plastic pollution. Look for manufacturers who provide comprehensive recycling options for their products. Embracing the idea of using materials designed for reusability can dramatically reduce environmental footprints.

Lastly, stay informed about innovative alternatives that aim to replace traditional plastics. Continuous advancements in polymer technology are making recycling and upcycling more efficient. This means that your choice of HDPE sheets could pave the way for not only sustainable construction practices but also foster a shift towards a more circular economy in design and manufacturing.

Lastly, stay informed about innovative alternatives that aim to replace traditional plastics. Continuous advancements in polymer technology are making recycling and upcycling more efficient. This means that your choice of HDPE sheets could pave the way for not only sustainable construction practices but also foster a shift towards a more circular economy in design and manufacturing.

When selecting HDPE sheets, the importance of choosing reliable suppliers cannot be overstated. A thorough comparison of manufacturers is essential to ensure quality and durability in your purchase. Start by researching the reputation of potential suppliers within the industry. Look for companies that have established a solid track record, characterized by positive customer reviews and testimonials. Engaging with industry forums and social media can provide insight into the reliability and performance of various manufacturers.

Additionally, consider the range of products a supplier offers. A manufacturer with a diverse selection of HDPE sheets is likely to have extensive experience and expertise. Examine their certifications and compliance with industry standards, as these are indicators of commitment to quality. Conducting direct inquiries about their sourcing and production processes can also shed light on their reliability. Ultimately, by focusing on reputable manufacturers with solid credentials, you can make informed decisions that align with current market trends and your specific needs.