Inquiry

Form loading...

- Phone

- E-mail

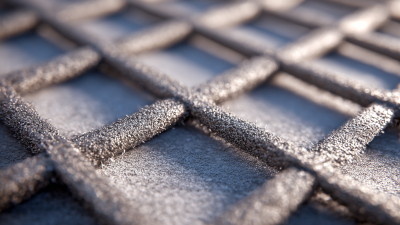

Geo Grid Mesh is a versatile material used in modern construction. It consists of a network of polymer fibers. This mesh enhances the strength of soils. The grids distribute loads over a wider area. This prevents settlement and cracking in structures.

In construction, Geo Grid Mesh plays a key role. It stabilizes roadways and underpins retaining walls. It can even aid in erosion control on slopes. Both engineers and contractors appreciate its benefits. This product helps create safer and more durable infrastructures.

However, like any material, it is not without flaws. Choosing the wrong type can lead to failure. Installation requires proper techniques and knowledge. Understanding the specific site conditions is crucial. This balance between innovation and caution guides successful applications of Geo Grid Mesh.

Geo grid mesh is an innovative material used in construction. It consists of a series of interwoven strands, forming a grid pattern. This design enhances soil stability and increases load-bearing capacity. By distributing loads evenly, geo grid mesh minimizes the risk of soil erosion and failure.

Research shows that using geo grid mesh can improve the performance of retaining walls by up to 50%. Projects that utilize geo grid technology often see reduced material costs. However, it is essential to assess soil conditions before implementation. Not all environments yield the same results. Some setups may lead to unexpected failures or require extensive maintenance.

Despite its advantages, misuse can occur. A lack of understanding of soil mechanics can lead to poor installation. Geo grid mesh is not a one-size-fits-all solution. Each construction site poses unique challenges. Engineers must carefully evaluate the conditions to avoid costly mistakes, such as inadequate strength or shortened lifespan of the mesh.

Geo grid mesh plays a significant role in modern construction techniques. The mesh comprises high-tensile strength materials, often polymer-based. This robust structure is designed to enhance soil stability and distribute loads efficiently. The grid pattern allows for easy integration with various soil types, improving overall performance in engineering projects.

The composition of geo grid mesh typically includes materials like polypropylene or polyester. These polymers offer durability and resistance to environmental factors. The structure is often designed with specific aperture sizes that facilitate drainage. This drainage capability prevents water accumulation, which is crucial for mitigating erosion risks.

While geo grid mesh offers many benefits, its production raises some concerns. The environmental footprint of plastic-based materials needs attention. In some cases, the long-term sustainability of geo grid mesh can be questioned. More research might be needed to assess the balance between short-term benefits and long-term impacts.

| Dimension | Description | Applications |

|---|---|---|

| Weight | Typically ranges from 200 to 500 g/m² | Used in soil stabilization |

| Aperture Size | Commonly between 5 to 12 cm | Integrates with aggregate materials |

| Material | Made from polymeric materials like polypropylene or polyester | Used in road construction and retaining walls |

| Strength | Tensile strength ranging from 15 to 100 kN/m | Enhances load distribution in pavements |

| Durability | Resistant to UV and chemical degradation | Suitable for long-term applications |

Geo Grid Mesh is a vital component in modern construction. Its applications are expanding as the industry embraces innovative methods. One key usage is in soil stabilization. Reports indicate geogrid systems can increase the load-bearing capacity of weak soils by up to 50%. This efficiency is crucial for roadways and foundations, especially in areas with poor subsoil conditions.

Another application of Geo Grid Mesh is in retaining structures. It is commonly used in retaining walls, helping to prevent soil erosion. The mesh provides reinforcement, ensuring stability in high-slope terrains. Research from industry professionals suggests that using geo grid solutions in these settings can reduce construction time by 30%.

Tips: Consider the specific soil type when selecting a Geo Grid Mesh. Each type is designed for various load and soil conditions. Also, invest time in proper installation techniques. Proper placement can enhance the performance significantly. Reflect on your project requirements and adapt the Geo Grid Mesh usage accordingly for the best results.

Geo grid mesh is becoming increasingly popular in construction, especially for soil reinforcement. This innovative material offers significant advantages. It provides support and stability to various soil types. By distributing loads evenly, it enhances the overall strength of the soil structure. In many projects, the use of geo grid mesh has reduced the need for extensive excavation. This can save both time and money.

One of the key benefits of geo grid mesh is its durability. It can withstand harsh environmental conditions. This longevity contributes to a more sustainable construction process. Additionally, it helps prevent soil erosion, which can be a major concern in many areas. Importantly, the material is lightweight and easy to transport. However, it’s essential to select the appropriate type for specific soil conditions. Misapplications can lead to ineffective reinforcement and project delays.

Incorporating geo grid mesh can also enhance drainage. Proper drainage is crucial for the longevity of any construction. On the flip side, contractors must carefully assess the project needs. If not done correctly, the results may fall short of expectations. Understanding soil behavior is vital. Projects that overlook this can face unexpected challenges later on.

Geo Grid Mesh plays a vital role in construction, providing stability and support in various environments. To install it effectively, understanding the specific environmental conditions is crucial. In soft soil areas, for instance, proper site preparation is essential. The surface should be compacted to prevent future settlement. This can involve removing organic material, which may compromise the installation.

In rocky terrains, drilling may be necessary to secure the mesh. Using heavy equipment can help in placing the geo grid accurately. According to industry reports, poorly installed geo grids can lead to 30% reduction in structural performance. Always consider soil type when planning the installation. Transfer load efficiently by adjusting the mesh type according to these factors.

Tips: Ensure the mesh is tensioned correctly. Loose installations can create weak spots. Regular inspections during and after installation can save time and money. It is vital to adapt techniques based on real-time conditions. Observing environmental changes post-installation can offer insights into the mesh’s performance. Addressing imperfections early can enhance long-term project outcomes.