Inquiry

Form loading...

- Phone

- E-mail

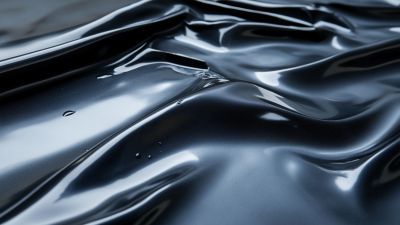

The construction industry is increasingly turning towards sustainable solutions, and one innovative application paving the way for eco-friendly practices is the use of "Geomembrana In Hdpe." According to a report by Research and Markets, the global geomembrane market is projected to reach $3.1 billion by 2025, driven by rising environmental regulations and an increasing need for waste management and containment solutions. Geomembranes, particularly those made from high-density polyethylene (Hdpe), offer exceptional chemical resistance and long-term durability, making them an ideal choice for applications in landfill liners, aquaculture, and water management systems. As the industry continues to seek efficient methods to mitigate environmental impact, the adoption of geomembrane technologies can significantly enhance sustainability in construction projects, aligning with the broader goals of reducing carbon footprints and promoting resource conservation.

HDPE geomembranes have emerged as a vital component in sustainable construction solutions, owing to their exceptional properties. High-Density Polyethylene (HDPE) offers remarkable chemical resistance, durability, and flexibility, making it ideal for various construction applications. These geomembranes not only serve as effective barriers against water and contaminants but also contribute to the longevity of infrastructure projects. Their impermeability ensures that leachates and pollutants are contained, significantly reducing environmental impact.

Moreover, HDPE geomembranes are lightweight, facilitating easier handling and installation on construction sites. Their resistance to UV radiation and extreme weather conditions enhances their performance and longevity, reducing the need for replacement and maintenance. Innovations such as incorporating recycled content into HDPE geomembranes further bolster their sustainability profile, aligning with modern construction practices aimed at minimizing waste and resource consumption. Consequently, the innovative properties of HDPE geomembranes position them as indispensable materials for creating environmentally friendly and resilient construction solutions.

Recent advancements in geomembrane technology, particularly with high-density polyethylene (HDPE), have significantly contributed to environmental sustainability in construction. According to the Global Geomembrane Market report by Mordor Intelligence, the geomembrane market is projected to reach USD 3.83 billion by 2026, driven by increased demand in waste management and environmental protection applications. HDPE geomembranes, known for their durability and impermeability, play a vital role in landfill liners and mining operations, preventing soil and water contamination.

Moreover, the implementation of innovative HDPE geomembrane solutions has enhanced the efficiency of stormwater management systems. The U.S. Environmental Protection Agency (EPA) reports that improper stormwater management contributes to 80% of the pollution in urban waterways. With advanced geomembrane designs, construction professionals can better control runoff, effectively reduce pollution, and promote water conservation techniques. As industries continue to adopt sustainable practices, HDPE geomembranes present a practical option for mitigating environmental impact while ensuring structural integrity in construction projects.

HDPE geomembranes have emerged as a critical component in sustainable waste management practices. In landfill applications, these durable barriers effectively prevent leachate migration, thereby protecting groundwater from contamination. One notable case study is the implementation of HDPE geomembranes in a state-of-the-art landfill in California, where thorough testing confirmed a significant reduction in environmental impacts. By utilizing these geomembranes, the facility not only complied with strict environmental regulations but also enhanced the efficiency of its waste containment system.

Another innovative application can be seen in the closure of temporary waste storage sites. In a project in the UK, HDPE geomembranes were used to cover a decommissioned waste facility, minimizing odor emissions and controlling rainfall infiltration. This case highlighted the material's versatility, as it can be tailored to meet site-specific needs and environmental conditions. The successful integration of HDPE geomembranes into these waste management strategies demonstrates their pivotal role in achieving sustainable construction solutions.

| Application Area | Geomembrane Type | Thickness (mm) | Waste Type Managed | Year Implemented | Sustainability Impact |

|---|---|---|---|---|---|

| Landfill Liner | HDPE | 2.0 | Municipal Solid Waste | 2018 | Reduced leachate contamination |

| Leachate Collection System | HDPE | 1.5 | Hazardous Waste | 2020 | Improved waste management efficiency |

| Sediment Control | Textured HDPE | 1.0 | Construction Debris | 2019 | Mitigated soil erosion |

| Dewatering | HDPE | 2.5 | Contaminated Water | 2021 | Enhanced water quality |

The use of HDPE geomembranes in construction is gaining momentum as a cost-effective solution that also promotes sustainability. These high-density polyethylene materials offer exceptional durability and resistance to environmental factors, significantly reducing the need for frequent replacements. When integrated into projects such as landfills, ponds, and reservoirs, HDPE geomembranes not only enhance structural integrity but also contribute to reduced long-term maintenance costs.

Tips: When selecting HDPE geomembranes for a project, consider the specific environmental conditions and loading requirements. Investing in high-quality materials can lead to greater performance and lower lifecycle costs, making it an economically wise decision. Additionally, collaborating with experienced suppliers can provide valuable insights into the best practices for installation and integration.

Incorporating HDPE geomembranes also aligns with the global push for sustainable construction methods. By minimizing waste and utilizing recyclable materials, these geomembranes can play a pivotal role in reducing a project's overall environmental footprint. Employing them in designs encourages innovation while ensuring economic viability, proving that sustainability and cost-effectiveness can go hand in hand in modern construction practices.

The geomembrane market is poised for significant growth, driven by increasing demand for sustainable construction solutions. From 2024 to 2032, the global geomaterial market is expected to expand from $476 million to $768.6 million, reflecting a compound annual growth rate (CAGR) of 6.2%. The versatility of HDPE geomembranes plays a critical role in this expansion, as they are widely utilized in various applications, including landfill linings, water containment, and green building practices.

Moreover, the geomembrane market alone exceeded $2.34 billion in 2023, with projections indicating a CAGR of approximately 5.5% through 2032, primarily fueled by the mining sector's growth. The integration of innovative geomembrane applications in green building constructions not only enhances sustainability but also responds to the increasing global emphasis on eco-friendly practices. As industries seek to adopt more robust and environmentally friendly methodologies, the advancements in geomembrane technology will be pivotal in shaping the future of sustainable construction.