Inquiry

Form loading...

- Phone

- E-mail

In the complex world of international trade, procuring high-quality Geo Grid Mesh is essential for ensuring stability and durability in construction projects. With the global Geo Grid Mesh market projected to reach USD 1.2 billion by 2027, driven by the escalating demand for innovative geotechnical solutions, understanding the nuances of supplier certification becomes paramount. According to a recent report by Grand View Research, the increasing emphasis on sustainable construction methods and the need for effective soil reinforcement solutions are propelling this industry forward. Therefore, navigating the labyrinth of certifications and quality standards is crucial for procurement professionals seeking to partner with reputable suppliers. This blog will serve as an ultimate guide, detailing best practices for sourcing superior Geo Grid Mesh while ensuring compliance with international trade regulations and quality benchmarks.

International trade certifications play a crucial role in the procurement of geo grid mesh, particularly as the demand for innovative infrastructure solutions continues to rise globally. As reported by the Global Geosynthetics Market Analysis, the industry is projected to reach $12.6 billion by 2025, growing at a CAGR of 11.5% from 2020 to 2025. This expansion underscores the necessity for compliance with international quality standards, which not only ensure product reliability but also facilitate smoother cross-border transactions.

Certifications such as ISO 9001 for quality management systems and ASTM standards for geosynthetic materials are pivotal in establishing trust among stakeholders. For instance, obtaining EN and ASTM certifications can significantly enhance product credibility in markets demanding high-performance materials. According to a recent study by MarketsandMarkets, approximately 60% of industry buyers consider certification as a key factor in their procurement decisions. Consequently, understanding and navigating the certification landscape can significantly impact a company's competitive edge in sourcing geo grid mesh, ensuring adherence to quality while meeting regulatory requirements across various regions.

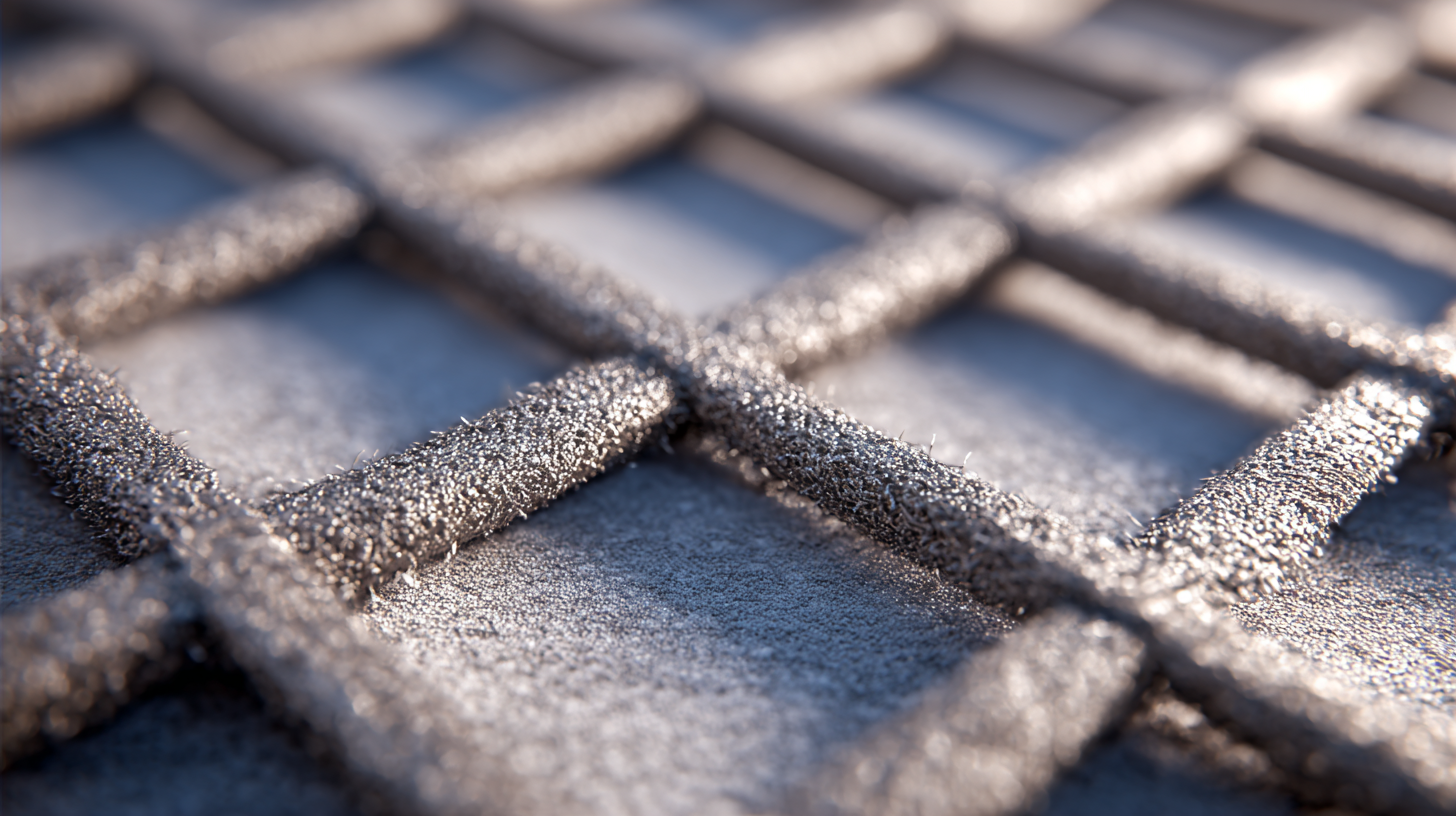

When procuring geo grid mesh products, understanding the key characteristics of different types is crucial for making informed decisions. Geo grid mesh products come in various materials and designs, such as polypropylene, polyester, and fiberglass, each offering unique properties. Polypropylene is lighter and generally cost-effective, making it ideal for drainage applications, while polyester provides higher tensile strength, suitable for reinforcing soil structures. Fiberglass, on the other hand, boasts superior durability, perfect for demanding environments.

When procuring geo grid mesh products, understanding the key characteristics of different types is crucial for making informed decisions. Geo grid mesh products come in various materials and designs, such as polypropylene, polyester, and fiberglass, each offering unique properties. Polypropylene is lighter and generally cost-effective, making it ideal for drainage applications, while polyester provides higher tensile strength, suitable for reinforcing soil structures. Fiberglass, on the other hand, boasts superior durability, perfect for demanding environments.

Tips: Always assess the specific requirements of your project, including load-bearing capacity, soil condition, and environmental factors. This will help you select the most appropriate geo grid type. Additionally, it’s advisable to consult with manufacturers or suppliers to get detailed product specifications and recommendations tailored to your needs.

In addition to material considerations, the mesh opening size and geometry play a significant role in performance. Larger apertures promote excellent soil interlock, while smaller openings can enhance soil confinement. Understanding these design aspects can lead to improved project outcomes and longevity of the geo grid mesh.

Tips: Before making a procurement decision, perform a side-by-side comparison of different geo grid mesh specifications. This analysis will ensure that you select a product that not only meets technical requirements but also aligns with project budget constraints.

Geo grid mesh is gaining traction across various industries, serving as a pivotal component in infrastructure projects due to its remarkable strength and flexibility. The construction sector has particularly embraced geo grid mesh in applications such as road reinforcement and slope stabilization. Its ability to distribute loads efficiently enhances the durability of roadways and prevents soil erosion, making it a preferred choice for civil engineering projects. Additionally, agricultural applications have seen the use of geo grid mesh to support soil structure and ensure better vegetation growth, highlighting its versatility.

In the realm of energy, geo grid mesh plays a critical role in the development of microgrids. As the demand for renewable energy sources increases, integrating geo grid mesh facilitates the construction of efficient and resilient energy systems. These microgrids not only enhance energy reliability in urban settings but also enable communities to harness locally generated power. As industries continue to innovate, the applications of geo grid mesh are expected to expand, solidifying its position as an essential resource in modern engineering and energy solutions.

When considering the procurement of geo grid mesh materials, a comparative analysis of different types is essential for optimal performance. The market offers several categories, including polymeric, steel, and composite geo grids. Each type has unique characteristics that cater to specific engineering needs. According to a recent report by MarketsandMarkets, the global geo grid market is expected to grow from USD 3.18 billion in 2021 to USD 5.71 billion by 2026, indicating an increasing reliance on effective soil reinforcement solutions.

Polymeric geo grids, which account for approximately 55% of the market share, are known for their corrosion resistance and flexibility, making them suitable for a variety of applications in road construction and soil stabilization. In contrast, steel geo grids offer superior tensile strength and load-bearing capabilities, often preferred in heavy load applications like retaining walls and embankments.

A study published in the Journal of Geotechnical Engineering highlighted that composite grids can provide frictional resistance that is 30% higher than traditional polymeric options, further enhancing soil stability in challenging environments.

Ultimately, the choice of geo grid mesh material significantly impacts project durability and performance. By aligning specific project requirements with the strengths of each material type, engineers can enhance the efficacy of their designs and contribute to sustainable infrastructure development.

When navigating the complex landscape of international trade certifications for geo grid mesh procurement, it is essential to understand the best practices that can greatly enhance your purchasing decisions. First and foremost, buyers should prioritize sourcing from manufacturers with established certifications such as ISO 9001 or other relevant international standards. These certifications not only ensure quality control but also signify that the manufacturer adheres to rigorous operational processes.

Tip: Always verify the certification credentials of your suppliers. Request documentation and, if possible, seek third-party validation to confirm that the products meet the necessary international standards.

Additionally, establishing strong communication channels with suppliers can provide insights into their production practices and certifications. Understanding their compliance with environmental and safety regulations will help you make informed decisions that align with your project requirements and sustainability goals.

Tip: Conduct regular audits or assessments on potential suppliers. This proactive approach can help identify any potential issues before they affect your procurement process and ensure that your suppliers remain in compliance with the necessary certifications.