Inquiry

Form loading...

- Phone

- E-mail

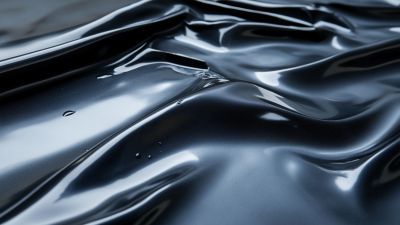

Selecting the right HDPE Geo Membrane for your project needs is a crucial step in ensuring the success and longevity of various applications, including landfill liners, pond liners, and water containment systems. With an array of options available in the market, making the right choice can be daunting. HDPE (High-Density Polyethylene) Geo Membranes are renowned for their excellent chemical resistance, durability, and flexibility, making them ideal for numerous environmental projects. However, each project has unique requirements, from the specific environmental conditions to the intended use and longevity of the membrane.

This guide aims to provide insights into the key factors you should consider when selecting an HDPE Geo Membrane, helping you navigate the complexities of the selection process and ultimately leading to informed decision-making for optimal project outcomes.

When selecting the right HDPE geomembrane for your project, it's crucial to understand the different types available in the market. HDPE geomembranes are primarily categorized based on their manufacturing process and application characteristics. The key types include textured and smooth geomembranes, each suited for specific purposes. Textured geomembranes offer superior friction resistance, making them ideal for applications requiring enhanced stability on slopes, while smooth ones are typically easier to install and clean, fitting well for containment applications like landfills.

Tips for Selecting HDPE Geomembranes:

1. Assess your project requirements: Consider factors such as the environmental conditions, type of soil, and the intended use of the geomembrane. This will help you determine the appropriate thickness and texture.

2. Review manufacturer specifications: Always consult product data sheets and specifications to ensure that the selected geomembrane meets the necessary compliance and performance standards relevant to your project.

3. Seek expert opinions: Engaging with industry professionals can provide valuable insights and recommendations on the best geomembrane type for your specific needs. Their expertise can assist in avoiding common pitfalls during installation and application.

When selecting the appropriate HDPE geomembrane for your project, the thickness and strength of the material are critical factors to consider. The thickness of the geomembrane typically ranges from 0.5 mm to 2.5 mm, and its selection largely depends on the specific application. For projects requiring robust containment, such as landfills or hazardous waste storage, a thicker geomembrane is essential to withstand punctures and tears that may occur due to soil movement and other external pressures. Conversely, for applications with less environmental stress, a thinner geomembrane may suffice, providing a cost-effective solution while still meeting compliance standards.

When selecting the appropriate HDPE geomembrane for your project, the thickness and strength of the material are critical factors to consider. The thickness of the geomembrane typically ranges from 0.5 mm to 2.5 mm, and its selection largely depends on the specific application. For projects requiring robust containment, such as landfills or hazardous waste storage, a thicker geomembrane is essential to withstand punctures and tears that may occur due to soil movement and other external pressures. Conversely, for applications with less environmental stress, a thinner geomembrane may suffice, providing a cost-effective solution while still meeting compliance standards.

Strength is another vital consideration, as it directly influences the geomembrane's durability under varying conditions. Important strength parameters include tensile strength, elongation at break, and resistance to chemical degradation. Understanding the environmental conditions your geomembrane will face—such as temperature fluctuations, UV exposure, and chemical interactions—is crucial for selecting a product that maintains its integrity over time. Therefore, conducting a comprehensive analysis of the project's requirements and anticipating potential challenges will help ensure that the selected HDPE geomembrane meets both performance and longevity expectations.

When selecting HDPE geomembranes for your project, it's crucial to evaluate their chemical resistance properties. HDPE, or high-density polyethylene, is renowned for its durability and strength, but its performance greatly depends on the specific chemicals it will be exposed to during its lifespan. Understanding the potential chemical interactions is essential for ensuring the longevity and effectiveness of the geomembrane in its application.

To assess the chemical resistance of HDPE geomembranes, consider the types of substances involved in your project. Begin by reviewing the chemical compatibility charts provided by manufacturers, which list various chemicals alongside their effects on HDPE. It's important to know whether the geomembrane will come into contact with solvents, acids, or other reactive materials. Conducting laboratory testing can provide additional insights into how the geomembrane will perform under specific conditions. This approach not only helps in selecting the appropriate material but also mitigates risks of leakage or failure when exposed to harsh environments.

| Property | Importance | Typical Values | Test Method |

|---|---|---|---|

| Chemical Resistance | Determines durability in harsh environments | Good resistance to acids and bases | ASTM D543 |

| Thickness | Affects strength and flexibility | 0.5 mm to 3.0 mm | ASTM D698 |

| Puncture Resistance | Protects against sharp objects | 300 N to 600 N | ASTM D6241 |

| UV Stability | Ensures longevity in outdoor use | Up to 50% for 3 years | ASTM G155 |

| Temperature Resistance | Critical for thermal stability | -40°C to 60°C | ASTM D746 |

When selecting the right HDPE geo membrane for your project, assessing environmental conditions is crucial to ensure optimal performance. Various factors such as soil characteristics, water table fluctuations, and temperature variations can significantly influence the longevity and effectiveness of the geo membrane. By conducting a comprehensive site assessment, engineers can understand how these elements interact with the geo membrane, leading to more informed material choices.

Additionally, the chemical composition of surrounding soil and water is vital in the selection process. Certain chemicals may degrade HDPE over time, reducing its barrier properties. Hence, it is essential to evaluate potential contaminants and their concentrations in the environment. Utilizing this information enables project managers to select the most suitable HDPE geo membrane that meets the specific demands of the project while ensuring environmental compliance and durability.

When selecting an HDPE geomembrane for your project, cost-effectiveness is a critical factor that requires a careful balance between budget constraints and the quality of the materials. While it may be tempting to choose the cheapest option available, this can lead to higher long-term costs due to potential failures and maintenance issues. A low-quality geomembrane may not withstand environmental stressors such as UV radiation, chemicals, or mechanical damage, ultimately compromising the project’s integrity and increasing overall expenditure.

Investing in a high-quality HDPE geomembrane, although initially more expensive, can result in significant savings over time. These products often offer superior performance characteristics, durability, and longevity, which can lead to lower maintenance costs and fewer replacements. Additionally, consider the long-term implications of regulatory compliance and environmental impact, which may impose further costs if subpar materials are used. Therefore, it is essential to evaluate potential suppliers based on their offerings, warranties, and track records to ensure that you strike the right balance between budget and quality in your selection process.