Inquiry

Form loading...

- Phone

- E-mail

Geo Synthetic Material has revolutionized construction and environmental projects. These innovative materials serve a variety of functions, from soil reinforcement to drainage solutions. According to the latest industry report by MarketsandMarkets, the global geo-synthetics market is projected to reach $18.27 billion by 2026, growing at a CAGR of 8.9%. This shows the increasing reliance on geo synthetic products.

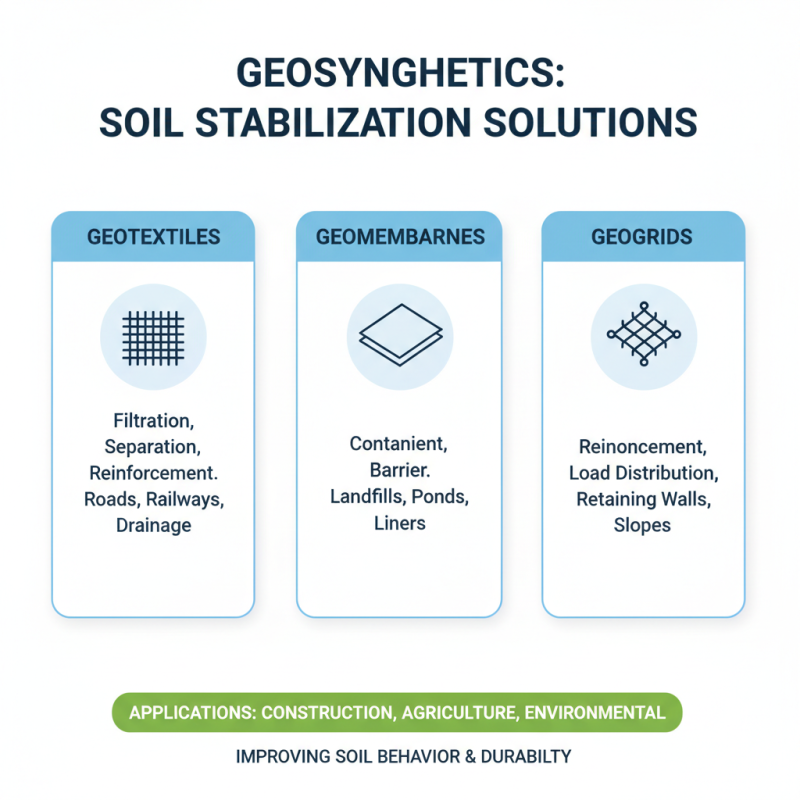

Applications for geo synthetic materials are vast, including landfills, road construction, and erosion control. These technologies help reduce project costs and enhance sustainability. For instance, geotextiles can filter water, while geomembranes are critical for preventing leakage in waste containment systems. However, despite the benefits, there are areas of concern. Some materials may degrade more quickly than anticipated, leading to performance issues.

The potential for geo synthetic materials is immense. However, their effectiveness and longevity need careful evaluation. As the industry continues to evolve, understanding the best applications for geo synthetic materials is essential. Each project should consider the unique challenges and requirements to maximize the benefits. Awareness of both the advantages and limitations will guide future innovations in this field.

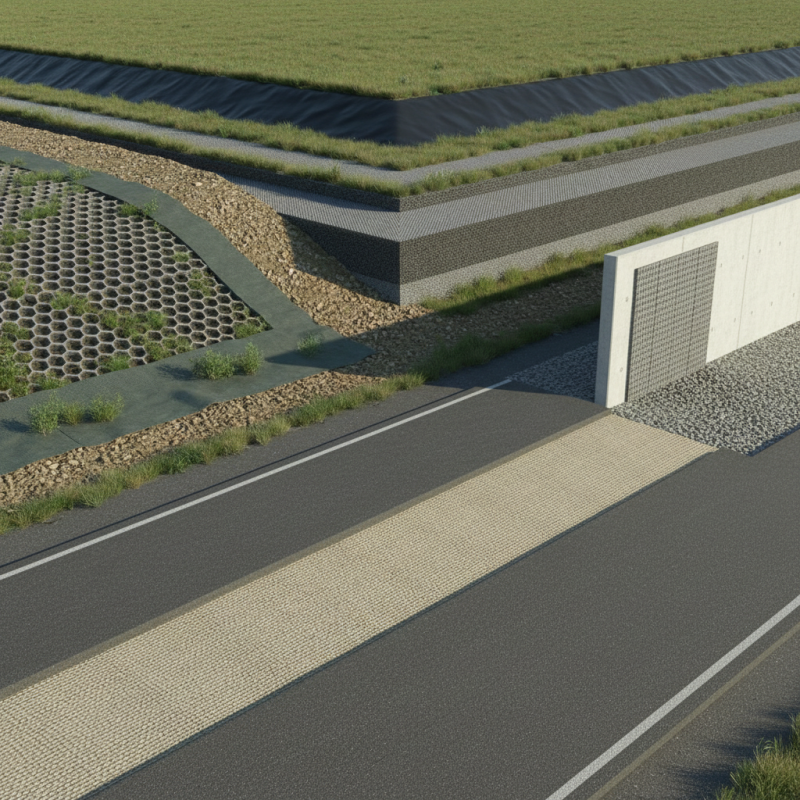

Geo synthetic materials play a crucial role in civil engineering. Their applications are diverse, ranging from road construction to soil stabilization. These materials improve structural integrity and enhance durability. For instance, geo textiles are commonly used in drainage systems. They help in filtering sediments while allowing water to flow freely through.

Using geo synthetic materials can sometimes be challenging. Proper selection is essential. If you use the wrong type, issues may arise. For example, not all geo membranes are suitable for every project. It's crucial to understand the specific environmental conditions. Failure to do so can lead to costly repairs later.

Tips: Always consult with an expert when planning your project. Testing the materials in a controlled environment may prevent future failures. Choosing geo synthetic materials involves careful consideration of project needs and local conditions. Don't rush into a decision; take your time to analyze all options.

| Application | Description | Benefits |

|---|---|---|

| Erosion Control | Used to prevent soil erosion on slopes and channels. | Reduces maintenance costs and increases site longevity. |

| Reinforcement | Enhances the load-bearing capacity of soil. | Improves stability and reduces settlement. |

| Drainage | Facilitates the movement of water away from structures. | Prevents flooding and water logging in construction sites. |

| Ground Stabilization | Provides support for weak soils during construction. | Increases safety and ensures project feasibility. |

| Landfills | Used in liners and covers to contain waste materials. | Minimizes environmental contamination. |

| Road Construction | Incorporated in pavement systems for better performance. | Enhances durability and reduces cracking. |

| Canal Lining | Serves to line canals to reduce seepage losses. | Improves water conservation and management. |

| Architectural Features | Used in decorative and functional architectural designs. | Enhances aesthetic appeal and functionality. |

| Mining Applications | Used for waste rock and tailings management. | Reduces environmental impact and improves safety. |

| Green Infrastructure | Integrates stormwater management with natural elements. | Promotes sustainability and ecosystem health. |

Geo synthetic materials play a crucial role in soil stabilization techniques. They are widely used in construction, agriculture, and environmental applications. These products include geotextiles, geomembranes, and geogrids. Each type serves unique purposes, impacting soil behavior positively.

Geotextiles, for instance, help separate soil layers. This separation allows the soil to maintain its integrity, reducing erosion. However, they can sometimes wear out faster than expected, especially in harsh climates. Geogrids reinforce soil structures, enhancing load distribution. Yet, improper installation can lead to failures, highlighting the need for skill and experience.

Also, geomembranes act as barriers against contaminations. Their impermeable nature prevents the mixing of soil and fluids. A flaw in installation can compromise their effectiveness, causing environmental risks. The learning curve with such materials can be steep, requiring constant adaptation and improvement in techniques. Understanding these aspects ensures that geo synthetic materials are used effectively for soil stabilization.

Geo synthetic materials play a pivotal role in environmental protection projects. They provide innovative solutions for waste containment, erosion control, and groundwater management. Research shows that these materials can reduce soil erosion by up to 80%, which is significant for preserving landscapes. Their lightweight and robust nature enhances their effectiveness in various applications.

In landfill projects, geo synthetics help prevent leachate from contaminating groundwater. For instance, geomembranes create barriers that isolate waste. According to the Environmental Protection Agency, these materials are crucial for maintaining safe landfill operations. The global market for geo synthetic materials is projected to reach $12 billion by 2025, highlighting the industry's growing reliance on them.

Tip 1: Always assess the local environment before choosing geo synthetic materials. Different regions have unique challenges.

Tip 2: Understand the lifespan of the materials used. Some may degrade faster than expected, leading to potential failures.

It is essential to stay updated on the latest advancements. A poorly chosen geo synthetic can lead to costly remediation later. Careful selection and application are vital for successful environmental projects.

Geo synthetic materials are transforming transportation infrastructure. These innovative solutions address key challenges in construction and maintenance. Notably, they enhance soil stability and reduce erosion. According to a report by the Geosynthetic Research Institute, 90% of the world’s roads use some form of geo synthetic technology.

One critical application is in road construction, where geo-grids and geo-textiles provide support. They distribute loads evenly, preventing pavement cracking. The International Society for Soil Mechanics estimates that the use of geo synthetics can cut costs by up to 50%. However, many projects still overlook the potential benefits of these materials. Proper training is often lacking, leading to mistakes that could cost more in the long run.

In addition to roads, geo synthetics play a vital role in environmental protection. They are used in landfill liners and drainage systems. These materials help contain waste and protect groundwater. Yet, the awareness of their benefits remains limited among engineers. Continuous education and better integration into standard practices are essential for maximizing their potential. Effective use can lead to safer, more sustainable infrastructure.

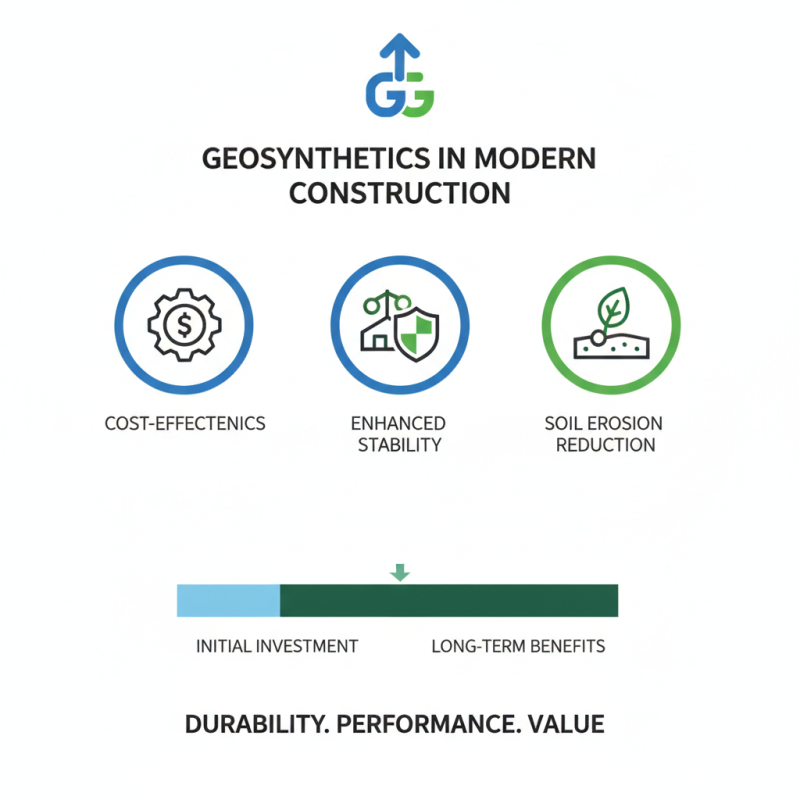

Geo synthetic materials play a pivotal role in modern construction. They can enhance the stability and longevity of various projects. Considering their cost-effectiveness is essential for decision-making. The initial investment may seem high, yet the long-term benefits often outweigh this. These materials reduce soil erosion and improve load distribution in structures.

Using geo synthetics can lead to savings on maintenance and repairs. For instance, some projects have reported a significant reduction in costs due to lower aggregate needs. This translates into fewer resources and labor hours. However, some challenges do arise in terms of installation. Not all crews are adequately trained, which can lead to mistakes.

In certain projects, geo synthetics may not perform as expected. Variables like climate and soil conditions can impact effectiveness. A thorough pre-project analysis is vital to mitigate such risks. Understanding the specific site conditions allows for better planning and cost management. Investments in training crews can also enhance project outcomes significantly.