Inquiry

Form loading...

- Phone

- E-mail

Geomembrane liners are becoming essential in various projects. They offer durability, flexibility, and resistance to environmental factors. These liners are made from synthetic materials like PVC or HDPE. Geomembrane liners provide a reliable barrier for liquids and contaminants. This makes them crucial in landfills, mining, and even agricultural applications.

Many projects benefit from using geomembrane liners. Their ability to prevent leakage protects the environment. Moreover, they can save costs by reducing maintenance needs. However, it is important to choose the right type. Not all geomembrane liners are created equal. Factors like thickness and chemical resistance must be considered.

While geomembrane liners have many advantages, challenges exist. Installation requires expertise to ensure effectiveness. If installed improperly, they may not serve their purpose. Environmental conditions can also affect their lifespan. A thorough evaluation is necessary before making a decision. Understanding these aspects helps optimize their benefits in your projects.

Geomembrane liners play a crucial role in environmental protection. These flexible membranes help prevent contamination in various projects. They are commonly used in landfills, water reservoirs, and mining operations. Their impermeability makes them ideal for isolating harmful materials. This reduces the risk of pollutants reaching the soil and groundwater.

The installation of geomembrane liners can also be cost-effective. By minimizing leakage, they help lower long-term maintenance costs. However, improper installation can lead to issues. If seams are not well-fused, water can seep through. Regular inspections are necessary to ensure functionality. These details matter significantly in maintaining safety standards.

Choosing the right type of geomembrane is essential. Various materials offer different advantages. Thickness, flexibility, and chemical resistance are key factors. While geomembrane liners are beneficial, they are not a magic solution. Environmental assessments must accompany their use. It’s important to consider the broader ecological impact.

Responsible usage is vital to truly achieve environmental protection.

Geomembrane liners are increasingly recognized for their cost-effective solutions in numerous projects. These liners play a critical role in waste containment and environmental protection. Their high durability reduces the need for frequent replacements, leading to substantial long-term savings. Projects involving landfills, ponds, or water containment directly benefit from their strength and flexibility.

Investing in geomembrane liners can lead to reduced labor costs as well. Installation is relatively straightforward, requiring less time and fewer workers compared to other materials. However, it's essential to ensure the proper installation to avoid potential leaks. A small oversight can lead to significant expenses down the line.

Moreover, geomembrane liners offer exceptional resistance to various chemicals and UV exposure. This quality not only prolongs their lifespan but also minimizes the risk of contamination. Yet, clients often overlook initial costs versus long-term benefits. Evaluating this balance is crucial in project planning. While geomembrane liners present clear financial advantages, their complexities warrant careful consideration.

Geomembrane liners are known for their durability and longevity in various projects. These products can withstand harsh environmental conditions. Their resistance to punctures and tears makes them ideal for applications in landfills, ponds, and reservoirs. Geomembranes typically last for decades, often exceeding 30 years if properly installed and maintained.

One must consider the installation process, though. If not installed correctly, even the best geomembranes can fail. UV exposure and chemical exposure are also factors to weigh. These can weaken the material over time. Regular inspections and maintenance help to ensure longevity but require commitment and resources. Even minor issues may lead to significant consequences.

While developing your project, pay attention to local climate and environmental factors. The lifespan of geomembranes can vary based on these conditions. Beyond design, understanding installation and maintenance is crucial. Achieving maximum durability and longevity takes strategic planning and execution.

| Benefit | Description | Lifespan (Years) | Application |

|---|---|---|---|

| Durability | Withstands harsh weather conditions and physical stress. | 20-30 | Landfills, mining |

| Hydraulic Performance | Excellent impermeability to liquids, reducing leachate. | 25-35 | Water containment, waste management |

| Cost-Effectiveness | Lower installation and maintenance costs compared to traditional liners. | 15-25 | Construction sites, agricultural ponds |

| Chemical Resistance | Resistant to a wide range of chemicals making it suitable for hazardous applications. | 20-30 | Chemical storage, industrial sites |

| Flexibility | Can be tailored to different shapes and sizes of projects. | 20-30 | Customized applications |

| Lightweight | Easier to transport and install than heavier alternatives. | 15-25 | Easy deployment scenarios |

| Environmental Protection | Prevents soil and groundwater contamination. | 30+ | Environmental remediation |

| UV Resistance | Available products have additives that protect against UV degradation. | 15-25 | Surface applications |

| Ease of Maintenance | Requires minimal maintenance compared to traditional options. | 20-30 | Various applications |

| Recyclability | Many geomembranes are recyclable, improving sustainability. | N/A | End-of-life considerations |

Geomembrane liners are crucial in various projects due to their exceptional chemical resistance. They can withstand harsh environments and exposure to numerous contaminants. A study by the Geosynthetic Research Institute highlights that certain geomembranes resist over 90% of common chemicals. This performance is vital for industries that deal with wastewater or hazardous materials. Choosing the correct liner can drastically reduce environmental contamination risks.

Many applications, like landfills, require durable barriers. In 2021, reports indicated that geomembranes maintained integrity against acids, solvents, and oils. These liners effectively prevent leachate migration. However, it's important to note that not all geomembranes perform equally. Some may fail under specific conditions, like extreme temperatures or prolonged UV exposure. These factors must be considered during material selection.

Furthermore, the longevity of geomembranes varies. While many can last over 30 years, factors like installation quality and site conditions influence their lifespan. Regular inspections and maintenance can identify potential issues early. Understanding the limitations and performance nuances is essential. Knowing these details empowers project managers to make informed decisions.

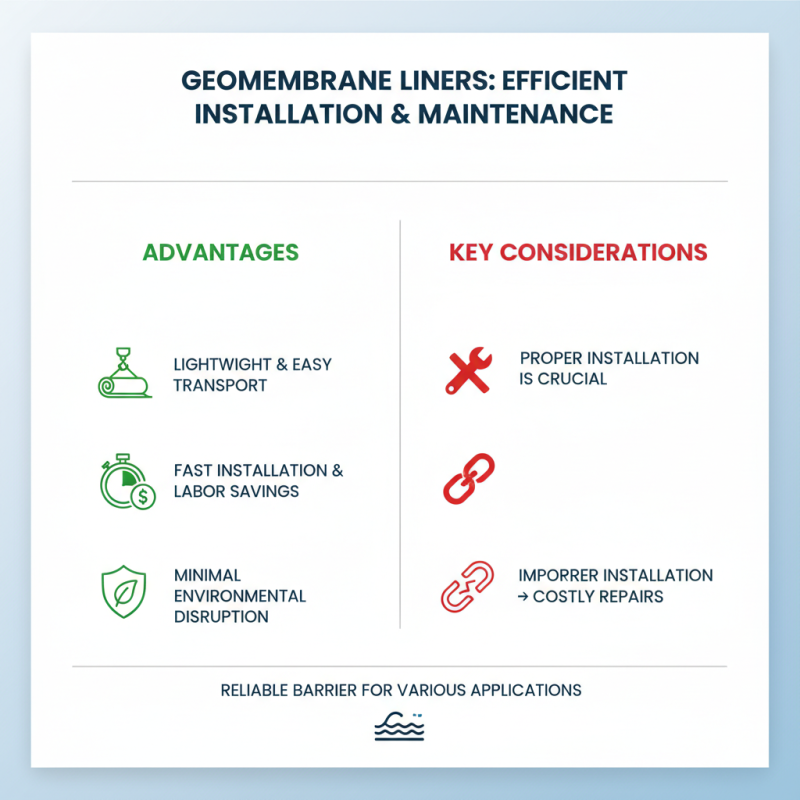

When considering geomembrane liners for your projects, installation and maintenance efficiency stand out. These liners provide a reliable barrier in a variety of applications. Their lightweight nature allows for easy transportation and installation. This can save both time and labor costs. A well-planned installation ensures minimal disruption to the surrounding environment. However, improper installation may lead to costly repairs.

Regular maintenance of geomembrane liners is crucial. Inspecting seams and joints can prevent leaks. Simple observations can lead to significant savings. Cleaning the surface reduces the buildup of contaminants. Yet, one must remember that maintenance requires ongoing commitment. Relying solely on the initial installation could be a mistake. Being proactive can extend the lifespan of these liners.

It's essential to train staff effectively in installation practices. Miscommunication can result in mistakes that are hard to fix. Yet, there may be challenges in training and ensuring everyone is on the same page. Ultimately, focusing on both installation and maintenance efficiency can lead to successful outcomes in your projects.