Inquiry

Form loading...

- Phone

- E-mail

The versatility and practicality of HDPE plastic sheets have made them a staple in various industries, ranging from construction to packaging. According to a recent report by the Plastic Industry Association, the demand for HDPE plastic is projected to grow steadily, with global consumption expected to reach 20 million tons by 2025. This surge is attributed to HDPE’s robustness, resistance to impact and chemicals, and its lightweight nature, making it a preferred material in many applications.

Industry expert Dr. Emily Thompson, a leading authority on polymer applications, emphasizes the significance of HDPE plastic sheets in modern manufacturing. She states, "The unique characteristics of HDPE plastic sheets allow for innovative solutions that are both cost-effective and sustainable." As businesses look to improve their environmental footprint, the recyclability of HDPE adds another layer of appeal, aligning with the growing consumer demand for eco-friendly materials.

This article delves into the top 10 uses of HDPE plastic sheets, showcasing their indispensable role across various sectors. Whether serving in structural applications, food safety scenarios, or even in the realm of art and design, HDPE plastic sheets offer a myriad of benefits that are worth exploring.

High-Density Polyethylene (HDPE) plastic sheets have gained significant popularity across various industries due to their unique properties. Characterized by high impact resistance, chemical stability, and low moisture absorption, HDPE is an ideal choice for applications requiring durability and reliability. According to Grand View Research, the global HDPE market was valued at approximately $66.6 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2030. This growth underscores the increasing reliance on HDPE in various sectors, including construction, automotive, and packaging.

One of the primary reasons for the widespread use of HDPE plastic sheets is their versatility. They can be easily fabricated and molded, making them suitable for applications such as protective barriers, signage, and storage tanks. Furthermore, the material's excellent resistance to UV radiation and chemicals makes it an ideal choice for outdoor applications and harsh environments. An industry report by Mordor Intelligence highlights that the construction sector alone is a major consumer of HDPE sheets, reflecting increased use in geomembranes for landfills and other containment systems. This adaptability, alongside sustainability considerations, as HDPE is fully recyclable, positions it as a material of choice for both traditional and innovative applications.

HDPE (High-Density Polyethylene) plastic sheets are renowned for their robust characteristics, making them an ideal choice in various applications. One of the most notable features of HDPE is its excellent resistance to impact, which ensures durability and longevity in both indoor and outdoor environments. This impact resistance is complemented by its superior chemical resistance, allowing HDPE sheets to withstand exposure to many acids, bases, and solvents without degrading or compromising structural integrity.

Another significant characteristic of HDPE plastic sheets is their lightweight nature, which makes them easy to handle and install across different projects. Despite being lightweight, these sheets do not sacrifice strength; they boast high tensile strength, rendering them suitable for applications ranging from construction to agricultural uses. Additionally, HDPE is moisture-resistant and does not absorb water, which further enhances its versatility and makes it a preferred choice for environments prone to spills or humidity. These qualities, paired with the material's recyclability, underline the practicality and eco-friendliness of HDPE sheets in various industrial and commercial sectors.

| Use Case | Description | Advantages | Common Thickness |

|---|---|---|---|

| Geothermal Systems | Used for insulating pipes in geothermal heat exchange systems. | Excellent thermal insulation and moisture resistance. | 1/4" - 1" |

| Packaging | Used for containers, bottles, and various packaging applications. | Durable, lightweight, and recyclable. | 0.5mm - 3mm |

| Construction | Used in various applications, including vapor barriers and flooring. | High strength and resistance to chemicals and impact. | 1/8" - 1" |

| Agriculture | Used for liners in ponds and tanks, as well as greenhouse coverings. | UV resistant and durable in various weather conditions. | 20 mil - 60 mil |

| Food Industry | Used in food packaging and processing equipment. | Non-toxic and resistant to various chemicals. | 0.5mm - 3mm |

| Furniture | Used in outdoor furniture and modular designs. | Weather-resistant and easy to maintain. | 1/4" - 1" |

| Marine Applications | Used for boat hulls and marine equipment. | Resistant to saltwater and various marine environments. | 1/4" - 1" |

| Signage | Used for outdoor signs and displays. | Durable and resistant to fading. | 1/8" - 1/2" |

| Playgrounds | Used in playground surfaces and equipment. | Safe, non-toxic, and provides cushioning. | 2" - 6" |

HDPE plastic sheets, known for their durability and versatility, have found significant applications in construction and building. One of the primary uses is as a vapor barrier in foundations and basements. This property helps prevent moisture intrusion, protecting structural integrity and enhancing indoor air quality. Additionally, HDPE sheets are employed in the construction of temporary site enclosures, providing dust and debris control while maintaining site safety during construction activities.

Another essential application is in the fabrication of custom formwork for concrete. The lightweight yet strong characteristics of HDPE make it an ideal material for creating reusable forms that can be easily manipulated on-site. Furthermore, HDPE sheets are widely used in the production of roof underlayment, offering an effective layer of protection against water and moisture while allowing for breathability. These applications showcase how the unique properties of HDPE contribute to more efficient, sustainable building practices in the construction industry.

HDPE (High-Density Polyethylene) plastic sheets are widely used in construction due to their durability, moisture resistance, and versatility. The chart below illustrates the top applications of HDPE plastic sheets in the construction industry.

High-Density Polyethylene (HDPE) plastic sheets have become increasingly popular in the food industry, particularly for their versatility and durability in packaging solutions. According to a report by the MarketsandMarkets, the global plastic packaging market is expected to reach USD 650 billion by 2026, driven largely by the demand for safer and more efficient food packaging. HDPE sheets are favored for their ability to resist moisture, chemicals, and contamination, which makes them an ideal choice for food contact applications. Their lightweight nature not only reduces transportation costs but also minimizes the environmental impact associated with heavier materials.

Furthermore, HDPE is inherently recyclable, aligning with the growing trend toward sustainability in the food sector. McKinsey & Company highlights that 66% of consumers are willing to pay more for sustainable food packaging, indicating a shift towards eco-friendly alternatives. Utilization of HDPE in packaging allows for safe storage of perishable goods while also maintaining compliance with health regulations, making it a reliable choice for food manufacturers. Additionally, the ease of fabrication and customization of HDPE sheets enables businesses to create tailor-made packaging solutions that can accommodate a variety of food products, from fresh produce to frozen goods. This flexibility positions HDPE as a critical component in modern food packaging strategies.

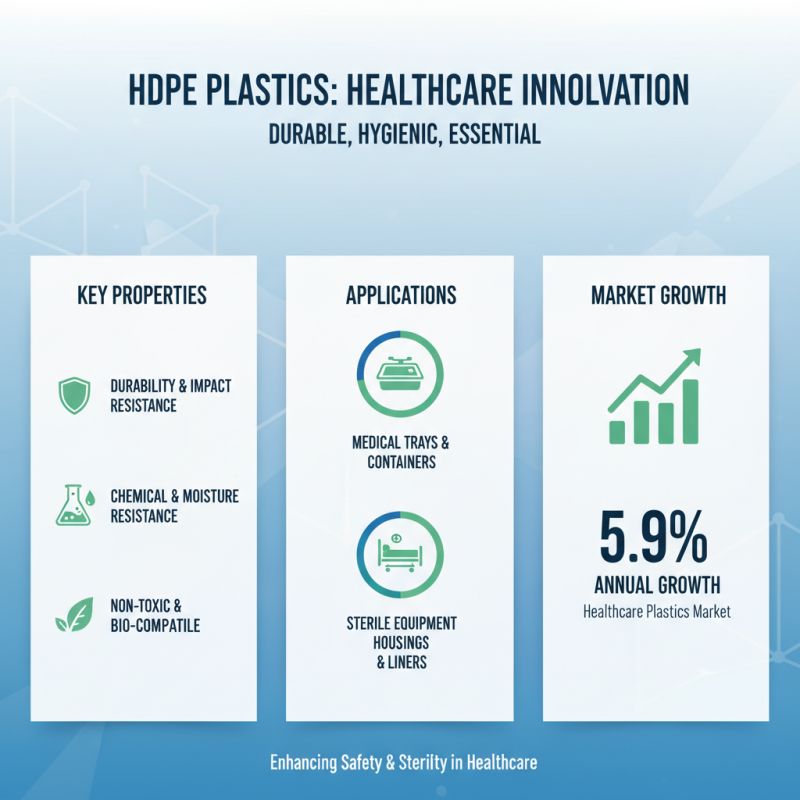

High-Density Polyethylene (HDPE) plastic sheets are making significant strides in the medical and health sectors due to their unique properties, such as durability, chemical resistance, and non-toxic nature. A report from the Healthcare Plastics Market suggests that the use of high-performance plastics like HDPE is expected to grow by 5.9% annually, driven by the increasing need for hygienic and sterile environments in healthcare settings. HDPE’s resistance to moisture and chemicals makes it an ideal choice for a variety of applications, including medical trays and containers, where hygiene and safety are paramount.

In addition to traditional uses, innovative applications of HDPE in the medical field include its incorporation into bespoke medical devices and laboratory equipment. For instance, HDPE sheets can be utilized in the manufacturing of protective barriers, essential during surgery to minimize contamination risks. The advantages of HDPE, including lightweight and ease of fabrication, streamline the creation of custom solutions tailored to specific medical needs. Furthermore, as the healthcare sector continues to evolve, the demand for sustainable materials like HDPE is expected to rise, aligning with the growing emphasis on environmental responsibility.

Tips for using HDPE sheets in medical applications include ensuring that all surfaces are properly cleaned and sterilized before use, as contaminants can compromise patient safety. Additionally, consider using HDPE sheets with high clarity when visibility is crucial, such as in diagnostic tools or patient observation panels. Investing in high-quality HDPE that meets industry standards can further enhance safety and scalability in medical operations and innovations.