Inquiry

Form loading...

- Phone

- E-mail

Geotextile Fabric for Driveways is an innovative solution for enhancing driveway durability. This material assists in stabilizing the ground beneath. It helps prevent the shifting of gravel or soil, which can lead to cracking or uneven surfaces.

When you lay down geotextile fabric, you're creating a solid foundation. The fabric works by allowing water to drain while keeping the soil intact. However, not everyone understands its proper application. Rushing through the installation may lead to frustrations later on.

Think about the specific needs of your driveway. Is it prone to flooding? Does it experience heavy traffic? Understanding these factors is crucial. Properly using geotextile fabric can extend the life of your driveway, but it requires careful planning and execution. Small mistakes can lead to significant issues down the line.

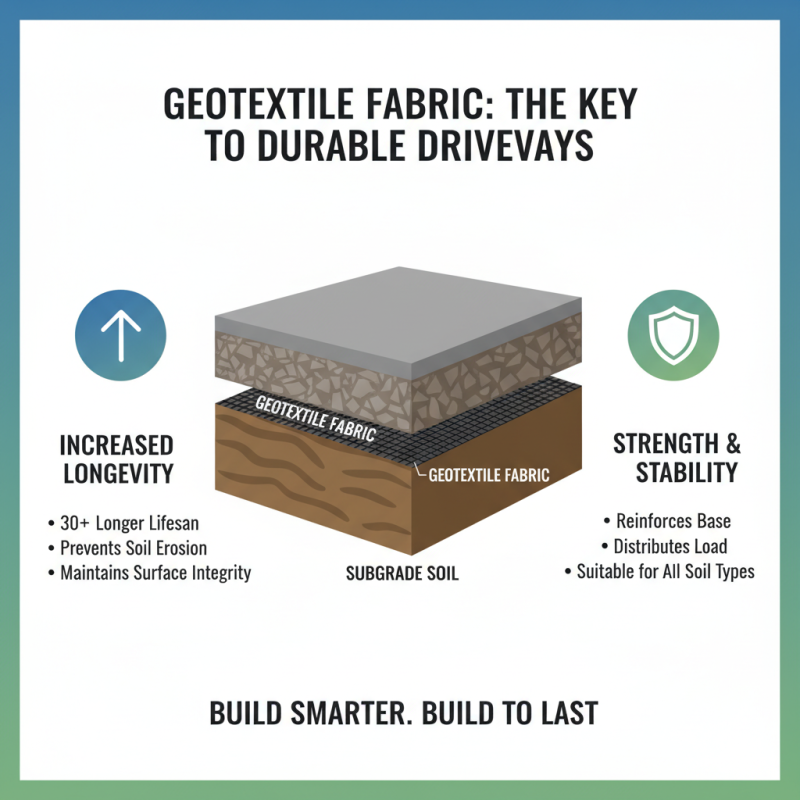

Geotextile fabric is an essential component for creating durable driveways. This material provides strength and stability, making it ideal for various soil types. According to industry research, using geotextiles can increase the longevity of a driveway by 30% or more when installed correctly. By preventing soil erosion, they help maintain the integrity of the driveway surface over time.

The benefits of geotextile fabric extend beyond longevity. It improves drainage, allowing water to flow freely and preventing pooling. A report from civil engineering studies indicates that a well-functioning drainage system reduces maintenance needs by up to 50%. However, improper installation can negate these benefits. It is vital to ensure proper layering and compacting of the fabric for maximum efficacy.

In addition, geotextile fabric is eco-friendly. It reduces the need for additional materials like gravel or asphalt. This can lower costs and minimize environmental impact. Still, homeowners must be cautious. Not all geotextiles are created equal, and choosing the right type is crucial. Research shows that the wrong selection can lead to quick degradation. This emphasizes the need for careful planning and assessment before use.

Choosing the right type of geotextile fabric for your driveway is essential for durability. Many options exist, but not all are suitable. First, consider the fabric's type—woven or non-woven. Woven fabrics offer better soil stabilization, while non-woven types excel in drainage. These differences impact your driveway's lifetime significantly.

Tips: Assess the soil quality before selecting. A weak base may require a stronger fabric. Also, consider environmental factors like drainage. Poor drainage can lead to fabric degradation.

Think about weight too. Thicker fabrics handle more traffic but are harder to install. If uncertain, consult professionals for advice. The investment in a suitable geotextile can save you money in repairs later. Measure your driveway accurately. An ill-fitting fabric might compromise stability.

Before installing geotextile fabric for your driveway, thorough preparation is key. Start by determining the area that needs coverage. Measure the space accurately. This helps avoid waste and ensures proper installation. Additionally, clear the area of any debris, rocks, or vegetation. An uneven surface can affect the fabric's effectiveness.

Next, assess the soil condition. If the soil is too soft or saturated, it may require treatment. Compaction might be necessary for stability. This step can prevent future sinking or shifting. Also, consider drainage. Proper drainage is essential to prolong the life of your driveway. Digging trenches or using gravel can aid in effective water management.

Finally, lay the groundwork for the fabric. It's essential to create a smooth, even base. Flatten any bumps or dips to achieve this. Unroll the geotextile fabric before installation to ensure it fits the designated area well. Pay attention to overlaps; they should be at least 12 inches to ensure full coverage. Taking these preparation steps seriously can lead to a more successful installation. Each detail matters for a sturdy and long-lasting driveway.

| Preparation Step | Description | Importance |

|---|---|---|

| Site Assessment | Inspect the area for drainage issues and soil quality. | Ensures the driveway has appropriate support and drainage. |

| Clear the Area | Remove any vegetation, debris, and existing pavement. | Prepares a clean surface for the installation of geotextile fabric. |

| Level the Surface | Ensure the ground is flat and properly graded. | Helps in proper water drainage and reduces settling. |

| Lay Geotextile Fabric | Place the fabric over the prepared surface, overlapping edges. | Prevents soil mixing and improves stability. |

| Add Aggregate Material | Add gravel or crushed stone on top of the fabric. | Provides a durable surface for the driveway. |

The installation process of geotextile fabric in driveway projects can significantly enhance durability and prevent soil erosion. Begin by excavating the driveway area to a depth of at least 6 inches. Ensure the ground surface is level and compact it well. Geotextile fabric should then be laid down, covering the entire area. A study by the Geosynthetic Industrial Association shows that using geotextiles can reduce settlement issues by up to 50%. This valuable data emphasizes their importance.

Tips: Make sure to overlap fabric edges by at least 12 inches. This prevents soil from mixing with the aggregate above. Accurate placement protects the fabric's integrity. After laying the fabric, fill it with gravel or crushed stone. Typically, a thickness of 3 to 4 inches is recommended. This allows for proper drainage and minimizes the risk of ruts forming. It's vital to regularly check for any areas where the fabric may show signs of wear.

However, not all installations go perfectly. Sometimes the fabric gets punctured during material placement. Other times, improper overlap can occur. These mistakes might lead to increased maintenance and repair needs. Reflect on each step of the process. Ensuring precise installation is vital for maximizing the benefits of geotextiles in your project.

When using geotextile fabric for driveways, proper maintenance is crucial for longevity. Studies show that driveways reinforced with geotextiles can last up to 50% longer than those without. However, neglecting maintenance can lead to issues. Regular inspection is key. Look for signs of wear, erosion, or pooling water. These signs indicate that the fabric may need repairs or replacement.

Cleaning is another essential aspect. Remove debris often to prevent buildup. A clean surface reduces moisture retention, which can weaken the structure. If weeds emerge, address them promptly. In fact, some reports highlight that unchecked vegetation can decrease the lifespan of driveways by as much as 30%. Using proper weed barriers in conjunction with geotextiles is often recommended.

Additionally, proper drainage is vital. Ensure that water does not accumulate. Waterlogged areas can compromise the fabric’s integrity. Employing a simple drainage system can alleviate this issue. Even professionally installed driveways can suffer from poor drainage. Hence, always evaluate your driveway’s performance after heavy rains. This proactive approach often saves time and resources in the long run.