Inquiry

Form loading...

- Phone

- E-mail

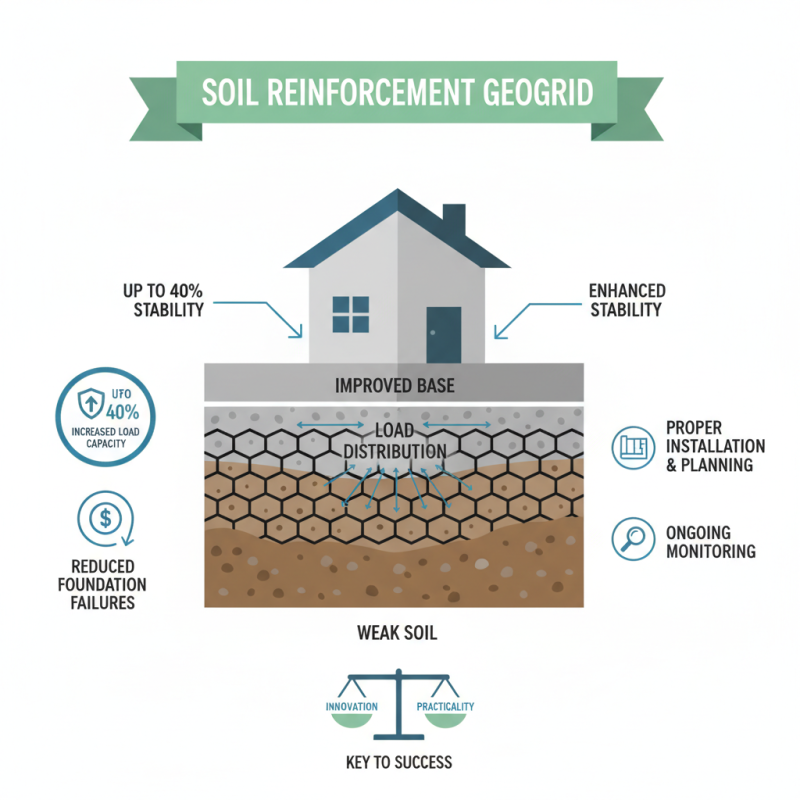

Soil Reinforcement Geogrid has gained recognition for enhancing foundation stability. This innovative product improves load distribution and minimizes settlement. Reports indicate that foundational failures can cost over $5 billion annually in the United States alone. Using Soil Reinforcement Geogrid can significantly reduce these failures.

The effectiveness of Soil Reinforcement Geogrid lies in its design. It consists of a grid-like structure that stabilizes soil by redistributing loads. In projects where geogrids are employed, engineers report up to a 40% increase in load-bearing capacity. This enhancement is crucial, especially in weak soil conditions. Yet, not every application achieves optimal results.

Improper installation or inadequate assessment of site conditions can lead to shortcomings in performance. These pitfalls underline the importance of careful planning and execution. It’s essential to choose the right type of geogrid based on specific project requirements. Furthermore, ongoing monitoring can help identify potential issues early. The balance between innovation and practicality is key in leveraging the benefits of Soil Reinforcement Geogrid.

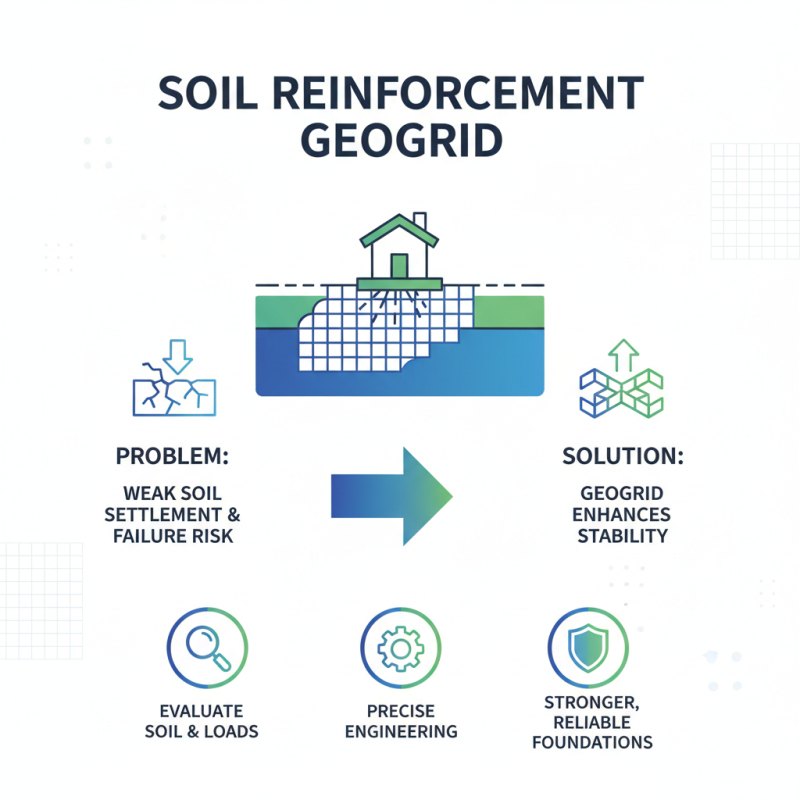

Soil reinforcement geogrid is an innovative solution for enhancing the stability of foundations. It is a mesh-like structure that provides additional support to soil. This material helps distribute loads more evenly, which is crucial in construction projects. The installation process requires careful planning. If not done properly, the benefits may not be fully realized.

Using geogrids can lead to significant improvements in soil strength. They reduce the risk of settlement and erosion. This is particularly vital in areas with poor soil conditions. The geogrid acts like a network, trapping soil and improving its load-bearing capacity. However, understanding the local environment is essential. Knowledge of soil types and conditions will influence the effectiveness of this method.

Challenges often arise during installation. For example, if the geogrid is not placed at the right depth, its benefits diminish. There's a learning curve involved. Contractors need to ensure proper alignment and tension of the grids. Attention to details can prevent costly mistakes. While geogrids offer clear advantages, reflection on their implementation can enhance future projects.

Soil reinforcement geogrids are essential for improving the stability of foundations in construction. They are engineered materials designed to enhance the load-bearing capacity of soil. Typically, these geogrids are made from various polymers or other synthetic components that provide significant tensile strength. According to the Federal Highway Administration, using geogrids can increase the load capacity of soil by up to 300%. This is vital in areas with soft or unstable soils.

Common types of geogrid materials include biaxial, uniaxial, and triaxial geogrids. Biaxial geogrids offer strength in two directions. They are ideal for base stabilization in road construction. Uniaxial geogrids are stronger in one direction. These are often used in retaining walls or steep slopes. Triaxial geogrids are designed for complex loading conditions. Their 360-degree strength allows for high-performance applications.

Despite their advantages, the effectiveness of geogrids relies on proper installation and soil conditions. If the soil is not adequately compacted, the benefits could diminish. Geogrids can be less effective in saturated soils. This poses challenges in certain environments. Understanding the site’s specific conditions is crucial. Engineers must assess these factors to maximize the benefits of geogrids in their projects.

Soil reinforcement geogrid is essential for stronger foundations. To begin, clear the site where you plan to install the geogrid. Make sure the ground is stable and well-drained. Next, assess the soil type. Different soils may require different approaches. You might find it challenging to deal with rocky or clay-heavy areas. Understanding your soil is crucial but can be difficult.

Once the site is ready, lay the geogrid flat over the prepared area. Make sure there are no wrinkles or overlaps. Keep it taut. If the geogrid shifts, it can lead to weak points in the foundation. Then, fill the geogrid with granular materials, like gravel or sand. This layer should be compaction-friendly. It is vital to compact the material thoroughly. Sometimes, people overlook this step and later encounter issues.

After adding the fill, check the elevation. It should be even and level. If it's not, you might need to adjust or add more material. Ensure there are no gaps. Reinforcing the edges is also important for stability. Many find this part tricky; it requires attention to detail. With patience and proper technique, a solid foundation can be achieved.

| Step | Description | Materials Needed | Time Required |

|---|---|---|---|

| 1 | Site Assessment: Evaluate soil conditions and determine requirement for geogrid. | Soil Survey Tools | 1-2 days |

| 2 | Excavation: Clear the area and excavate to the required depth. | Excavator, Shovels | 2-3 days |

| 3 | Base Layer Preparation: Install a base layer of gravel or crushed stone. | Gravel, Compactor | 1 day |

| 4 | Geogrid Installation: Lay the geogrid in the prepared area. | Geogrid Material, Fasteners | 1 day |

| 5 | Backfill: Fill the area with soil, compacting as you go. | Soil, Compactor | 1-2 days |

| 6 | Final Grading: Level the surface and prepare for the final structure. | Grader, Soil | 1 day |

Soil reinforcement geogrid is a powerful tool for creating stronger foundations. By enhancing soil stability, it reduces the risk of settlement and failure. When designing foundations, precise planning is crucial. Engineers should evaluate soil types and loading conditions carefully. Often, existing soil may not provide the necessary support. In such cases, geogrid can bridge weaknesses effectively.

Incorporating geogrid requires expertise. Placement must be methodical, ensuring proper overlap and tension. It’s essential to avoid common errors like insufficient anchoring. These mistakes can lead to foundation issues down the line. Regular inspections during installation help identify any gaps in the process. Additionally, applying geogrid in layers allows for better load distribution. Understanding the specific site conditions improves performance significantly.

While geogrid enhances stability, some limitations exist. For example, it may not work as well in extremely soft soils. Oversized loads can still challenge its effectiveness. Continuous evaluation and adjustments are necessary to adapt to site-specific challenges. This iterative approach leads to more resilient foundations. Innovating in materials and techniques can further enhance geogrid applications in construction.

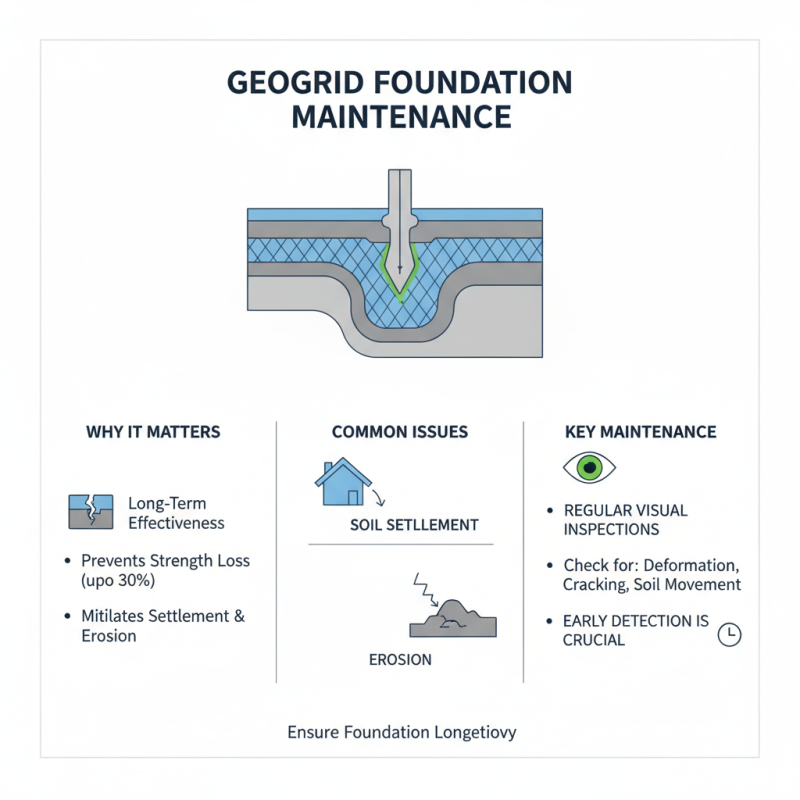

Geogrid-reinforced foundations require regular maintenance and inspection to ensure their long-term effectiveness. Studies show that poorly maintained geogrid systems can reduce their strength by up to 30%. Soil settlement and erosion are common issues. Regular visual inspections help identify signs of deformation, cracking, or soil movement early on.

Key factors include soil moisture levels and vegetation growth. Excess water can weaken the geogrid's effectiveness, while invasive roots may disrupt the geomaterial. Monitoring environmental conditions helps maintain stability. Moreover, physical inspections should occur at least twice a year. Gradual shifts in soil can go unnoticed, leading to costly repairs later.

Documentation of inspections is crucial. A study by the Federal Highway Administration emphasizes the importance of record-keeping. Detailed reports help track changes over time. Also, employing advanced technology for subsidence detection can enhance maintenance efforts. New sensors provide reliable data. Yet, these solutions can be costly and require training. Balancing affordability and effectiveness remains a challenge for many in the industry.